With the development of personal computers, numerical systems penetrated into various industries. The same goes for manufacturing. Today, the advantages of CNC machining are welcomed by numerous manufacturers in many industries for their manufacturing and manufacturing applications.

CNC systems have become an integral part of modern machining technology. “CNC” stands for Computer Numerical Control, and its principle is that the machine tool mechanism is connected and unified by a special digital control system. A machine operation can definitely replace manual work. At EVERGREEN, CNC prototyping technology has greatly improved due to revolutionary innovations in CNC machine tools. Regarding traditional machining vs CNC machining, we have the following deep understanding:

CNC machining

Principles of conventional and CNC machining

The system consists of a hardware part and a software part for computing purposes. The operator interacts with the software to monitor machine parameters and create NC programs. All machining processes involve the controlled movement of the cutting tool. However, the biggest difference between traditional machining processes and today’s more advanced technologies is the means of control.

In the early days of machining, all knives were controlled by hand to some extent. Machinists manually adjust their mills and lathes, using levers or wheels to point the sharp edge of the cutting tool at the appropriate part of the workpiece. This is still a common technique, where professional machinists can machine materials with high precision. Tracers and patterns can also be used to improve accuracy and repeatability.

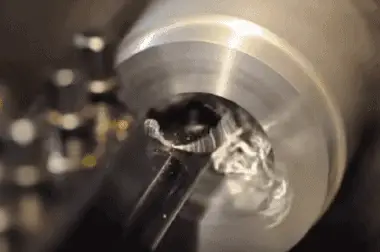

However, there are now alternatives to manual machining, the most important of which is CNC machining or computer numerical control machining, which was introduced in the 1940s and 1950s. CNC machining involves using a computer to guide a machine’s cutting tools. Rather than relying on a human machinist to move the cutting tool to different parts of the workpiece, digital instructions guide the machine to precise coordinates that allow it to operate without assistance.

An NC program is basically a list of instructions about how a machine tool should handle a particular part. The NC hardware reads the ancient program line by line and tells the machine to act accordingly.

Conventional machining now means that all machine tool movements are directly controlled by the operator. He chooses when to move the tool and feed, when to stop and where. Operators mostly use gauges and specialized rulers embedded in the joystick for greater precision.

Advantages of CNC machining

Safe processing

CNC machining usually refers to precision machining that is numerically controlled by a computer. Therefore, it can be controlled by the program instructions of the CNC machine tool, and the whole processing process is automatically carried out according to the program instructions. The machine tool has a high degree of automation, which greatly reduces the labor intensity of workers.

Currently, many CNC machines can run unattended throughout the machining cycle, freeing up the operator for other tasks. This has several side benefits for CNC users, including reduced operator fatigue, fewer errors due to human error, and consistent and predictable machining times for each workpiece.

CNC machining saves lives. The operator is safely isolated from all sharp parts by a special protective structure. He can still see what’s going on in the machine through the glass, but he doesn’t need to go anywhere near the mill or the spindle. The operator also does not have to touch the coolant. Depending on the material, some liquids may be harmful to human skin.

Processing economy

Today, conventional machine tools require constant attention. I mean, the operator moved every part of the tool himself. This means that each worker can only work on one machine. When the CNC era arrived, things changed dramatically. Most parts take at least half an hour to process per setup. But the CNC machine does the cutting part by itself. There is no need to touch anything. The tool moves automatically and the operator simply checks for any errors in the program or setup. Having said that, CNC operators find they have a lot of free time. This time can be used to work with other machines. So, one operator, many machines. This means you can save manpower.

Minimum setting error

Another advantage of CNC technology is the consistency and precision of the workpiece. Typical accuracies of today’s CNC machines are two thousandths to four-thousandths of an inch or 0.05 to 0.10mm, with repeatability close to or better than eight-thousandths of an inch or 0.02mm. This means that once a program is validated, two, ten, or a thousand identical parts can easily be produced with the same precision and consistency. Mass production can be achieved, and product quality is easy to control.

Traditional machine tools rely on the operator’s proficiency with measuring tools, and of course, good workers can set parts with great precision. However, there are only a handful of excellent domestic operators. This is why many CNC systems use dedicated coordinate measuring probes. It is usually installed in the spindle as a tool, and its position is determined by the probe touching the stationary part. After that, determine the zero point of the coordinate system to minimize the setting error.

Excellent machine tool condition monitoring

For condition machining, the operator must almost “feel” his machine. This means that he has to determine machining failures and dulling tools based on instinct and experience. Even so, his decision may not be optimal. Modern CNC machining centers add a lot of different sensors. Torque, temperature, tool life, and other positional information can be monitored as the workpiece is machined. Based on this information, you can make better decisions.

For example, you see that the temperature is too high. Higher temperatures mean tool wear, worse metal properties, etc. All you have to do is lower the feed or increase the coolant pressure. Clearly, machining is the most common manufacturing method today. This piece-by-piece process of removing material has been created since time immemorial and is now a well-established precision manufacturing tool. Every industry uses machining to some extent. Without exception. However, some industries benefit more from processing than others.

Stable reproduction accuracy

Because CNC machines follow computer instructions, they are extremely precise—more precise than even the most skilled human engineer. Most CNC machines have an accuracy of about 0.02mm, which means complex parts can be manufactured to very tight tolerances. Eliminating errors is a top priority for manufacturers, and CNC machines greatly reduce the possibility of errors.

Fewer test runs

Traditional machining inevitably has some test parts. The worker has to get used to the technology and he will definitely miss something while doing the first part and testing the new technology. There are ways for CNC systems to avoid trial runs. They employ a visualization system that enables operators to actually see what happens to the inventory after all the tools have gone through.

Complex surfaces are easy to manufacture

It is almost impossible to manufacture complex surfaces with high precision using conventional machining methods. It requires a lot of physical labor. CAM systems can automatically form toolpaths for any surface. You don’t have to use any effort at all. This is one of the greatest advantages of modern CNC machining technology.

Higher cutting parameters

High-speed machining is possible because of the closure of the cutting zone. At this speed, the chips fly around at high speed. The chips are followed by a spray of coolant because when it comes to high-speed machining, the coolant is under high pressure. When the speed reaches 10000rpm or more, manual operation is simply impossible. With high cutting speeds, it is important to keep the feed rate and chip width stable and prevent vibration. Manual implementation is not possible.

Higher machine flexibility

Since these machines are run by computer programs, running different workpieces is as simple as loading different programs. This also brings another benefit, fast conversion. Since these machines are very easy to set up and run, and programs can be loaded easily, they have very short setup times.

The traditional machining methods are milling machines for grooves or planes, lathes for cylinders and tapers, and drilling machines for holes. CNC machining can combine all of the above functions in one machine. With the ability to program toolpaths, you can replicate any motion on any machine. So, we have milling centers that can make cylindrical parts and lathes that can make slots. All to reduce part setup.