What is Steel?

You probably come into contact with steel on a daily basis – from kitchen knives to the skeletons of skyscrapers, steel is everywhere. Simply put, steel is a metal alloy with iron (Fe) as its main component and carbon (C) content between 0.02% and 2.1%. It has iron at its core, but by adding carbon and other alloying elements (such as manganese, chromium, nickel, etc.), it gains strength, hardness and functionality far beyond that of pure iron.

The carbon content determines the properties of the steel: low carbon steels (e.g. 0.1% carbon) are soft and easy to mold, making them suitable for making car shells; high carbon steels (e.g. 1% carbon) are hard and wear-resistant, often used for knives and springs. And by tweaking the alloying formula (adding chromium to make stainless steel, for example), steel can also withstand corrosion, high temperatures and even radiation.

It can be said that steel is the cornerstone of human industrial civilization – the world produces about 1.9 billion tons of steel annually, supporting almost all key areas such as construction, transportation, energy, etc. Moreover, with a steel recycling rate of over 85%, it is a benchmark material for the circular economy.

How is Steel Made?

The core objective of steel making is to transform iron ore into a material that can meet your specific needs by controlling the carbon content and removing impurities. The prevailing processes fall into two categories: the Blast Furnace-Boast Oven (BF-BOF) method and the Electric Arc Furnace (EAF) method.

Blast Furnace – Converter Method (BF-BOF)

This is a traditional process, suitable for mass production. The process is divided into three steps:

- Ironmaking: Iron ore (e.g. hematite), coke and limestone are thrown into a blast furnace where, at a high temperature of 2,000°C, the coke is burned to produce carbon monoxide, which reduces the iron oxides in the ore to liquid pig iron (containing about 4% carbon).

- Steelmaking: Pig iron is poured into a converter and blown into pure oxygen to remove excess carbon and impurities (e.g., sulfur, phosphorus) through an oxidation reaction that reduces the carbon content to a target value (e.g., 0.2%).

- Refining: Addition of manganese, silicon and other elements to adjust the composition, or continuous casting into billets and subsequent rolling into profiles.

Suitable scenario: Need to mass produce general-purpose steel (e.g. construction rebar), but with high energy consumption and carbon emissions (over 70% of the global steel industry).

Electric Appliance Furnace Steelmaking (EAF)

If you’re concerned about the environment, the electric furnace method may be more appealing to you – it uses scrap steel as a raw material, melts the metal through the high temperatures generated by the electric arc (3000°C or more), and then adjusts the composition.

- Advantages: energy consumption is 60% lower than blast furnace method, carbon emissions are reduced by 70%, and the production is flexible and suitable for small quantities of specialty steels (e.g. stainless steel).

- Limitations: Dependent on scrap supply, costs may rise if the regional recycling system is not perfect.

Industry Trend: With the carbon-neutral target advancing, the global share of electric furnace steel has exceeded 30%, and China plans to increase the proportion of electric furnace steel to more than 15% by 2025.

Core Properties of Steel

Steel is not “one material”, but rather a large family of materials with different formulations that give it a wide variety of properties. The following are the three core properties that determine its use:

Dissociation

Strength is the “skeleton” of steel, that is, its ability to resist deformation and fracture, commonly used indicators for yield strength and tensile strength.

Tensile strength: ordinary carbon steel up to 500MPa (equivalent to the size of the fingernail cover area to withstand 5 tons of weight), and advanced alloy steel (such as martensitic aging steel) even exceeded 2000MPa.

Increase strength: can be quenched, tempered and other heat treatment, or add vanadium, niobium and other trace elements, can refine the grain structure, so that the strength multiplied.

Malleable

Ductility is the ability of steel to deform plastically and determines the feasibility of processing such as stamping and forging.

Elongation: Mild steel can be stretched to 20% of its original length without breaking, while cast iron crumbles almost as soon as it is bent.

Key process: The hot rolling process improves ductility, which is why rebar can be easily bent into the shapes needed for construction and also absorbs energy during earthquakes.

Corrosion Resistance

Rust is the natural enemy of steel? Not necessarily!

Stainless Steel: With the addition of 10.5% or more chromium, a dense chromium oxide film forms on the surface, insulating it from water and oxygen. Marine grade stainless steel (e.g. 316L) also incorporates molybdenum to resist seawater erosion.

Galvanized Steel: Taking advantage of the fact that zinc is more active than iron, it allows the zinc to corrode preferentially and protects the internal steel.

Advantages of Steel

- Recyclability: Steel can be recycled indefinitely without degradation – the global recycling rate is over 85%, and 70% of the material in an end-of-life car can be put back into the production line.

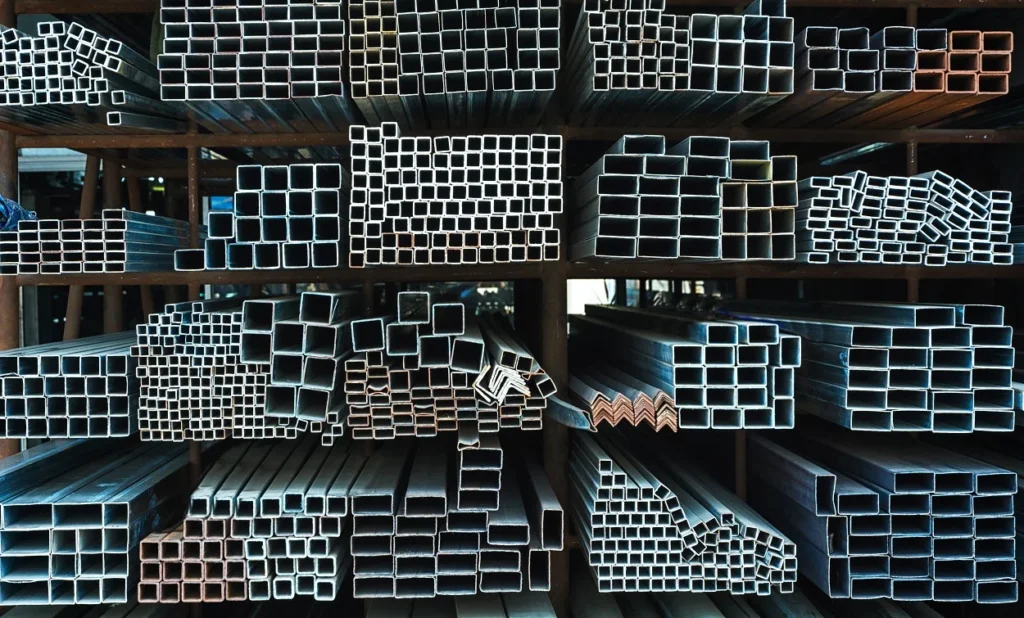

- Plasticity: From millimetre precision gears to bridges spanning kilometres, steel can be moulded through a variety of processes, including casting, forging, and welding.

- Economical: Scale production has brought the cost of carbon steel down to as low as $0.50 per kilogram, 1/3 the cost of aluminum and 1/50 the cost of titanium.

Disadvantages of Steel

There is no such thing as the perfect material, and if you’re going to use it, you’ll need to deal with some of the limitations below:

- Weight issue: Density up to 7.8g/cm³, often replaced by titanium alloys or carbon fiber in the aerospace field.

- Corrosion risk: Ordinary carbon steel loses 0.1mm thickness per year in wet environments, requiring regular maintenance or switching to stainless steel (2-4 times more costly).

- Controversial energy consumption: Conventional blast furnaces emit about 1.8 tons of CO₂ per ton of steel, and need to shift to hydrometallurgy and CCUS (carbon capture) technologies.

- Low-temperature brittleness: Certain steels become brittle below -20°C, and Arctic piping requires specialized low-temperature steels (e.g., nickel-alloyed steels).

Main Types of Steel

Here are the five main types and some of their characteristics:

Stainless Steels

When you need steel that can fight rust, stainless steel is the way to go.

Core formulation: at least 10.5% chromium (Cr), nickel (Ni) and molybdenum (Mo) are commonly added.

Stainless steel types:

- 304 Stainless Steel (18% Chromium + 8% Nickel): food grade standard for cutlery, kitchen countertops.

- Stainless steel 316 (2% molybdenum): resistant to seawater corrosion, standard for ship parts, coastal building railings.

- 430 stainless steel (low nickel): lower cost, suitable for non-highly corrosive scenarios such as washing machine inner tubs.

Tips: Medical surgical instruments need to use 316L (low carbon version), to avoid high temperature sterilization precipitation of carbide triggered contamination.

Carbon Steel

If you’re looking for value for money, carbon steel is an affordable material.

Three major classifications:

- Mild steel (C≤0.25%): easy to weld molding, car body, furniture skeleton.

- Medium carbon steel (C 0.25%-0.6%): hardness enhancement after quenching, ideal for gear and shaft parts.

- High carbon steel (C ≥ 0.6%): extremely hard, but poor weldability, commonly used in springs, cutting tools.

Tips: supermarket shelves with cold-rolled carbon steel, thickness error can be controlled in ± 0.01mm, to ensure that the laminate flat load-bearing.

Alloy Steel

When your project requires a steel with good overall performance, try alloy steels with rare elements added.

Performance Customization:

- Manganese steel (11- 14% Mn): the stronger the impact, the higher the hardness, used for excavator teeth, bulletproof steel plate.

- Silicon steel (3%Si): excellent magnetic permeability, transformer core saves over ten thousand dollars in annual electricity costs.

- Boron steel (0.001%B): automotive A-pillar material, tensile strength of 1500MPa after thermoforming, the key to save life in a collision.

Tips: Mining machinery wear parts can be used Cr-Mo alloy steel instead of more expensive carbide, life extension of 3 times.

Tool Steel

The “scalpel” of the manufacturing industry, built for high-strength machining.

Four main categories:

- High Speed Steel (HSS): Containing tungsten (W) and cobalt (Co), the tool retains its hardness at 600°C, increasing machining efficiency by 50%.

- Hot work die steel (such as H13): add vanadium (V) to resist thermal fatigue, die casting mold life up to 200,000 times.

- Cold work die steel (such as D2): high carbon and high chromium, stamping stainless steel plate edge is not easy to collapse.

- Plastic mold steel (e.g. P20): pre-hardening treatment, eliminating the need for post-processing heat treatment.

Tips: Small precision punching dies are made of powder metallurgy tool steel, which has less impurities and uniform hardness.

Weathering Steel

Want a product with its own “rust colour” and save on maintenance? Try weathering steel.

- Self-healing principle: add Cu, P, and Cr elements, prompting the surface to generate a stable Feooh rust layer (thickness of about 50μm), preventing further corrosion.

- Classic example: Corten steel is used for the internal supports of the Statue of Liberty in New York, which have not been replaced for 100 years.

- Tips: Initial rain will flow down the rust water, need to design the drainage groove to avoid polluting the wall, 2-3 years after the rust layer stabilized.

Uses of Steel

The application scenario of steel involves a very large number of industries, and the steel consumed globally every minute could build three Eiffel Towers:

Construction field:

Q345B low alloy steel is used for the core cylinder of ultra-high-rise buildings, with a seismic grade of 8.

Assembled steel homes are 70% lighter and two times faster to construct than traditional concrete buildings.

Transportation equipment:

- The high-speed rail car body is made of SUS301L stainless steel with 3mm thickness to withstand 40 tons of compression force.

- DP980 duplex steel for battery pack housing in electric vehicles, with 30% higher energy absorption in case of collision.

Energy equipment:

- Wind turbine tower with welded structure of S355NL steel plate supporting 8MW wind turbine (height 140 meters)

- SA508Gr.3 steel for reactor pressure vessels in nuclear power plants, withstanding 170°C high temperature water corrosion for 40 years.

Life Details:

- The miniature motor shaft in your cell phone is made of 440C stainless steel with a diameter of 0.3mm accuracy ±0.001mm.

- Antibacterial stainless steel (with Cu/Ag ions) has been used for hospital door handles with a 99.9% sterilization rate.

Let Evergreen Customize Your Steel Parts

When you need non-standard parts, Evergreen can provide you with a full chain solution from material selection to molding:

Material Think Tank:

- Inventory covers 200+ steel grades, from aerospace grade AMS 6520 to food grade SUS444 for immediate stocking.

- Free material corrosion resistance comparison test is provided to help you avoid selection mistakes.

Precision molding:

- Five-axis linkage CNC machining of complex surfaces with tolerance control ±0.005mm.

- The laser cuts 20mm thick plates at speeds of up to 3m/min, with smooth cuts that do not require secondary grinding.

- Precision casting, sand casting and many other casting processes with high output.

Certification Guarantee:

- We have passed many certifications such as IAFT16949, ISO3834, EN15085, ISO14001, ISO00 and ISO45001.

- Parts exported to the European Union automatically generate material CE certificates with zero delays in customs clearance.

Tips: Last year, a new energy automobile enterprise reduced the weight of steering knuckle by 18% through our optimization solution, saving 2.4 million yuan in annual material cost.