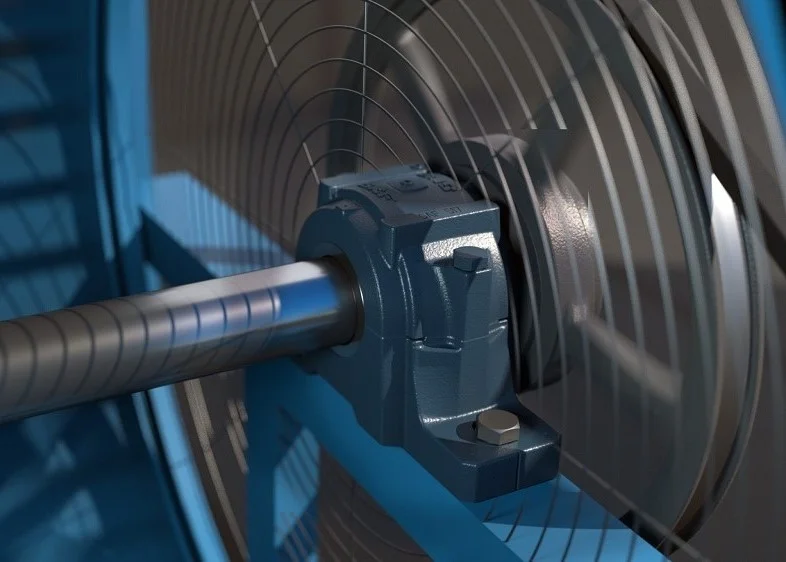

Plummer Blocks are manufactured using high-quality ductile iron. Our Plummer Blocks are industrial-grade and durable, which can extend the life of your equipment by 30% and reduce maintenance costs by 50%.

Of course, we can provide you with plummer blocks in a variety of materials, as well as a variety of end covers and some special sealing options to ensure product adaptability and tightness.

As a manufacturer of high-quality Plummer Blocks, it is our responsibility to provide you with products that you are satisfied with. Our greater advantage is to provide you with the perfect solution.

If your plummer block is used in mining machinery, then you will face the dust getting into the inside of the Plummer Block, which leads to bearing wear and lubrication failure; the equipment will also be subjected to a lot of impacts and loads during operation, and the Plummer Block will be easily deformed and fractured, and you will need to shut down as soon as you need to do maintenance, which affects the production efficiency. Our solution is to adopt double sealing design and choose ductile iron GGG50 as the material, which can improve the pit impact capacity by 30% and also effectively extend the service life, and design the mounting holes on the top, so that the maintenance can be completed without dismantling. Perfectly solve the problem of mining machinery Plummer Block.

If your Plummer Block is used in agricultural machinery, then our solution is to provide you with IP65 protection level to reduce the hazards of dusty and humid environment on Plummer Block; and use wear-resistant material to reduce the frequency of your maintenance of the machine; and we will also optimize the production process to reduce your purchase cost.

We are very aware that each different industry faces different problems when using plummer blocks. However, EVERGREEN has done a lot of plummer blocks in different industries and has helped customers solve many problems. During this period, we have also accumulated a wealth of experience. We welcome you to consult with us, and we will work with you to explore feasible solutions to solve your pain points.

EVERGREEN’s plummer blocks give you many customizable options, which is one of the highlights of our products.

We have produced many types of plummer blocks, such as split plummer blocks, non-split plummer blocks and flanged housings, our engineers are very familiar with the products of plummer blocks, and can easily understand your needs, so no matter what kind of needs you have, they can be satisfied at EVERGREEN. Our engineers are very familiar with plummer blocks and can easily understand your needs, so no matter what kind of needs you have, they can be satisfied at EVERGREEN.

Our plummer block can serve many industries, no matter what industry you are in, you can use our plummer block to install the bearings firmly on the equipment, so that the radial and axial positioning is accurate and does not deviate during operation.

Here are EVERGREEN’s main workshops, including metal casting, forging, machining, and metal works. You are more than welcome to visit our factory. Leave your plummer block project to EVERGREEN and we will definitely give you a satisfactory answer.

At EVERGREEN, not only is the process complete, but we also have a full range of inspection facilities, which is in line with the vision of our business: to provide products that meet and even exceed the needs of our customers. And we have been working hard to that end.

If there are no special requirements, we basically use high-grade ductile iron cast in one piece, which is 35% stronger than traditional cast iron. We also carry out a surface carburizing treatment on the plummer block to form a hardened layer of 0.3mm. Combined with our unique sealing structure, it can ensure 20,000 hours of maintenance-free operation in harsh environments.

Our plummer blocks are modular in design, and the bearing holes are machined to the H7 tolerance defined in ISO, which can be perfectly adapted to bearings from major brands such as SKF, NSK and TIMKEN. The hole sizes range from φ20mm to φ480mm. Of course, we also accept special custom sizes, which can be quickly customized within 48 hours.

Send us a message to get a personalized quotation with up-to-date prices or for

any other questions. Our team would be more than happy to get back to you ASAP.

We have been committed to innovation, product quality, and perfection for over 25 years.

Call Us at: +86 139 6969 0461

Sign up to get Newsletter and Industry Updates.