EVERGREEN can customize the production of various types of bearing housings for you, and both the material and style can be highly customized.

Our bearing housings are made of high-quality raw materials that are corrosion-resistant and highly durable, and are suitable for most industrial applications. They can also provide dust and waterproof performance.

The reason why EVERGREEN bearing housings are so popular is that they have many different features to meet the needs of our customers.

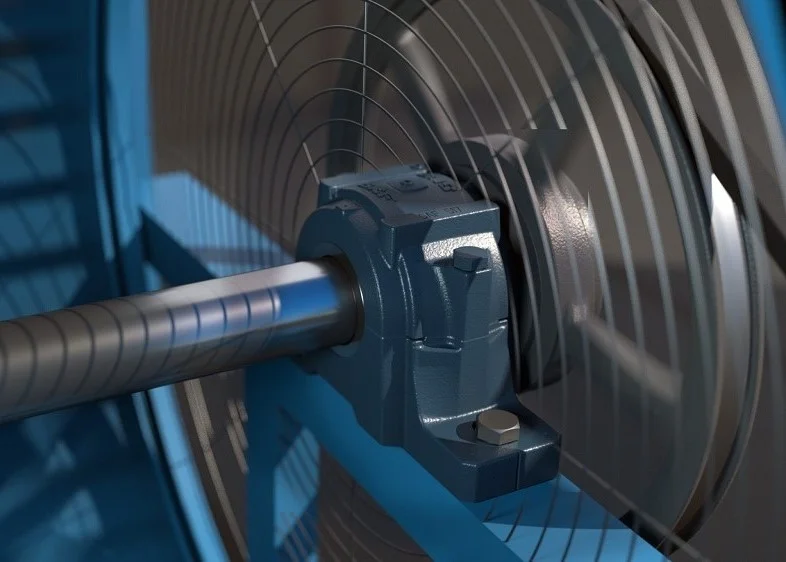

At EVERGREEN, you can find various types of bearing housings, such as Split Plummer block housing, Non-split Plummer block housing, Flanged housing, Take-up housing, and Two-bearing housing. They can all fit your bearings perfectly, so that they can perform to their maximum potential. Here are some of the bearing housings we have manufactured.

Bearing housings play an important role in many industries. They not only protect the bearings, but also absorb vibrations and protect the equipment.

Here are EVERGREEN’s main workshops, including metal casting, forging, machining, and metal works. You are more than welcome to visit our factory. Leave your bearing seat project to EVERGREEN and we will definitely give you a satisfactory answer.

At EVERGREEN, not only is the process complete, but we also have a full range of inspection facilities, which is in line with the vision of our business: to provide products that meet and even exceed the needs of our customers. And we have been working hard to that end.

We can provide you with flexible bearing block design services. You can provide complete drawings for direct production, or submit some basic parameters to us, even just an idea. Our team of R&D engineers will design and optimize your bearing block structure with their extensive industry experience.

We can also create 3D models for your bearing blocks and provide free 3D printing services.

Every bearing housing we produce has passed both dynamic simulation testing and physical load testing. Dynamic simulation analysis We use finite element analysis to simulate the stress distribution under actual conditions, and we also use physical test benches to perform fatigue tests.

This ensures the stability and durability of the product under rotational speed and radial/axial loads. If you are still not convinced, we can provide a test data report with the shipment.

For some harsh use environment, we can provide some special design solutions for your reference:

For high temperature environment, we can use heat-resistant alloy steel as raw material, and then with graphite lubrication groove design, so that the working temperature of the bearing housing can reach 350 ℃.

For high humidity or salt spray environment, you can choose stainless steel as the substrate + galvanized surface treatment, can successfully pass the 72 hours of neutral salt spray test, the protection level reaches C5-M standard.

We are supportive of complex structure customization, a variety of casting processes with five-axis machining centers, can produce a variety of complex bearing housings, and even curved surface of the mounting base.

You only need to provide a schematic of the assembly space, we will balance the strength of the mechanism and space utilization through modular design, our maximum machining size up to 2000mm*1500mm*800mm.

Send us a message to get a personalized quotation with up-to-date prices or for

any other questions. Our team would be more than happy to get back to you ASAP.

We have been committed to innovation, product quality, and perfection for over 25 years.

Call Us at: +86 139 6969 0461

Sign up to get Newsletter and Industry Updates.