Currently, the status of aluminum casting parts is irreplaceable in the industrial world. It is known for its lightweight, high strength, corrosion resistance, low cost, high productivity, and other advantages, and it has an important role in many industries; this article will give you a detailed understanding of cast aluminum and how to choose the right casting for your project.

What is cast aluminum

Aluminum casting is a broader term that refers to the process of heating solid aluminum or aluminum alloy to a molten state, then pouring the heated liquid aluminum into a pre-prepared product mold or heat-resistant cavity and waiting until the liquid aluminum cools down to a solid state to get an aluminum casting of your desired product.

Aluminum and many aluminum alloys require a low melting point and have a low viscosity when melted, but it cools to form a solid with high strength. The material and construction of the cavities used for casting also vary, and there are many different processes.

Why use cast aluminum

Aluminum parts obtained through cast aluminum have many advantages that are unmatched by other materials, and I’ll show you the advantages below so you can understand why you should use cast aluminum:

Light weight and high strength

Cast aluminum parts have a lower density and excellent mechanical properties, so it has a lighter weight compared to materials such as steel, but it is second only to expensive magnesium and titanium in strength and stiffness, which makes cast aluminum parts ideal for lightweight design. It is particularly important for industries that need to reduce the weight of their products (e.g., automotive, aerospace), which can improve fuel efficiency, reduce material costs, and improve safety to some extent.

Corrosion resistance

Aluminum castings have good corrosion resistance and are not easily eroded by air, water and chemicals, which allows it to maintain good performance and appearance in a variety of harsh environments. It is suitable for use in environments such as long-term outdoor or marine.

Ease of processing

Aluminum alloy is less ductile than pure aluminum metal, which is softer than it, and has good machinability, which makes it easier to process, enabling the manufacture of complex shapes and delicate parts. Cast aluminum has become an ideal choice for the manufacture of a wide range of complex parts and assemblies.

Thermal and electrical conductivity

Aluminum has good thermal and electrical conductivity, so it is widely used in the manufacture of heat sinks, electronic equipment or products that require good thermal and electrical conductivity.

Cost-effectiveness

Aluminum casting is more cost-effective than other metal processing methods. Aluminum is a relatively inexpensive raw material that is easy to process, and cast aluminum can be highly automated, saving time and labor costs.

Sustainability

Aluminum is a renewable material that can be recycled and reused many times, and the scrap produced during the aluminum casting process can also be recycled, so aluminum casting products have a lower impact on the environment and better sustainability.

Different Aluminum Casting Processes

Die casting

Die casting is a common metal casting process that is particularly suited to the production of low melting point alloys such as aluminum, zinc, and magnesium. In the die-casting process, liquid metal is injected into a mold to eventually form the desired casting. Die casting can produce parts with high precision and quality. Moreover, it has a complete automation system and is suitable for mass production.

The design and quality of the mold directly affect the quality of the die-casting. A mold usually consists of two halves, the upper and lower molds. The gap between them is the shape and size of the product.

Investment casting

Investment casting is a high-precision casting process, also known as precision casting. This process is usually used to manufacture parts with complex shapes, precise dimensions, and high surface quality requirements, such as aero-engine parts, automotive parts, and medical equipment parts.

Products produced by investment casting are highly accurate, have good surface quality, and require little or no subsequent machining. However, investment casting also has higher costs and longer manufacturing lead times.

Sand casting

Sand casting is suitable for the manufacture of small metal parts, starting with the creation of a set of molds based on the shape and size of the part to be manufactured. The mold is then filled with special sand to obtain a two-part cavity, usually silica sand, which is able to remain undeformed at high temperatures and is strong enough to withstand the pressure and heat of casting. The two cavities are combined and cast.

Although automation is possible, casting is usually done manually. Sand casting has the advantages of low cost, short production cycle and suitable for mass production. However, its cavity is disposable and cannot be reused.

Metal casting

Metal casting is somewhat similar to die casting in that two permanent halves of a die are clamped together to form a complete cavity, and the die is usually made of iron, steel, or aluminum. Unlike die casting, metal casting fills the mold by gravity rather than pressure. This results in cast parts with a better surface finish and higher strength.

Vanishing mold casting

Vanishing mold casting is similar to investment casting, but it uses a polystyrene foam mold instead of wax, which is dipped in paint to form a ceramic shell. When the shell is dry, the foam mold is baked, and the molten metal is poured into it, resulting in the desired casting.

Shell casting

A mold for shell casting usually consists of two parts: one to form the shape of the casting and the other to form the internal cavities and details. The surface of the mold then needs to be repeatedly coated and dried with a special refractory material, such as silicate sand, to form the shell shape to ensure that the shell has sufficient strength and refractory properties.

Shell casting is faster and less costly than normal sand casting and is suitable for medium to large castings that require higher accuracy.

Vacuum die-casting

Vacuum die casting is an advanced metal casting process which uses a vacuum environment in the casting process and injects the molten metal or alloy into the mold through negative pressure. Under the vacuum environment, the presence of air bubbles can be effectively reduced, so it can produce high-density, non-porous castings with a high surface finish.

Centrifugal casting

The principle of centrifugal casting is to inject liquid metal into the high-speed rotation of the casting so that the liquid metal can do centrifugal movement so as to fill the casting. Due to the role of centrifugal force, the liquid metal can be well filled with casting and help the liquid metal gas and inclusions in the exclusion; it will also affect the crystallization process of the metal, thus improving the mechanical and physical properties of the castings.

The use of centrifugal casting out of the parts of high hardness and strength, porosity, slag, and other defects is less, as well as process yield and other advantages.

Cast Aluminum VS Forged Aluminum

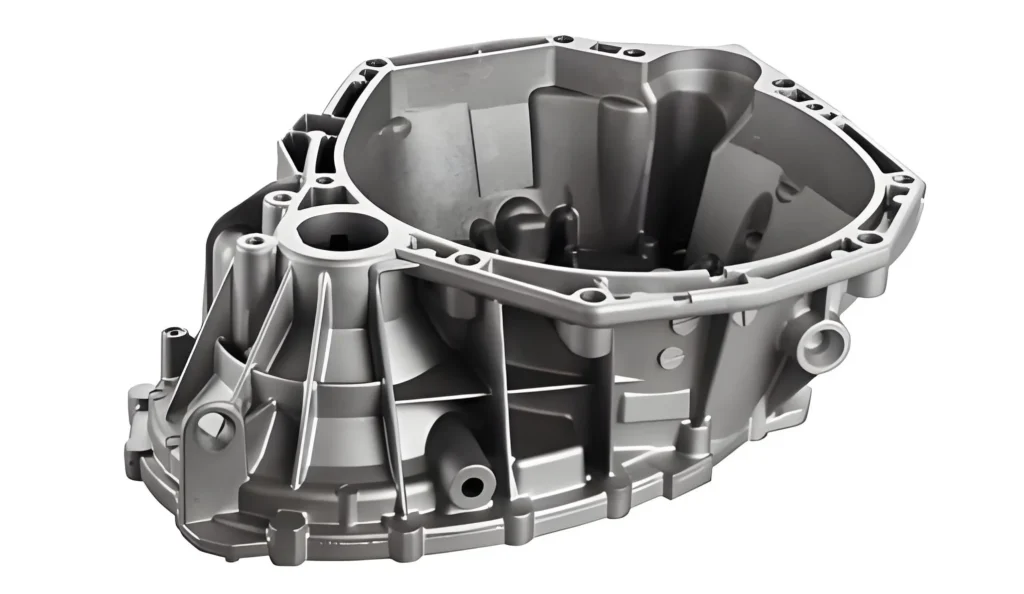

Cast aluminum is formed by melting an aluminum alloy, injecting it into a mold, and cooling it to form a casting. Cast aluminum usually has a high degree of forming freedom. Still, it has a relatively large grain structure, low strength, and hardness compared to wrought aluminum and is usually used for parts that require a high degree of forming complexity. For example, automotive engine housings, aerospace parts, etc.. Cast aluminum is relatively inexpensive to produce but may require additional machining for specific engineering requirements.

Forged aluminum is an aluminum alloy that is heated to a higher temperature and then formed into the desired shape by hammering or pressure from a forging machine. Wrought aluminum undergoes deformation and machining during the manufacturing process and, as a result, has a more detailed grain structure and higher density. It typically has higher strength, hardness, and wear resistance for applications requiring high strength and durability. Examples include automotive suspension systems and aircraft structural components. Wrought aluminum is usually more expensive to produce but usually results in higher mechanical properties.

How to Choose The Suitable Aluminum Casting Process

In fact, there are many factors to consider when trying to choose the right aluminum casting process, including the complexity of the part’s shape, the need for material properties, production cost, and cycle time. Here are some suggestions for choosing an aluminum casting process:

Design complexity

If you have a complex part design, then you can choose die casting. It can produce aluminum parts with complex shapes and precise dimensions because it uses high pressure to inject aluminum liquid into the mold, which is able to fill small cavities well. Sand casting, however, is limited by the difficulty of making molds and the inability to fill them with aluminum when dealing with complex parts.

Speed of production

If you want to produce parts quickly, then die-casting is the way to go. This is because it can be molded in a single pass in a short period of time and can be done continuously, making it suitable for rapid production of large quantities. In contrast, sand casting and investment casting can be slower because they have longer production cycles and are usually suited to small production runs.

Production costs

If you want to reduce the cost of casting, then sand casting is less expensive. It is relatively inexpensive to make molds for low-cost, high-volume production. Die casting, on the other hand, is more expensive in terms of equipment and mold making, but it can spread the cost by producing in larger quantities.

Performance requirements

Different casting processes differ in terms of product performance. Die casting, vacuum casting, and centrifugal casting provide higher product density and strength and are suitable for applications requiring higher hardness, strength, and wear resistance, such as automotive parts or industrial machinery. Sand casting and investment casting may be slightly less capable but are still suitable choices for some lightweight structures or non-critical components.

Surface quality

If your parts require a high level of surface quality, then you can choose die casting or precision casting, which can provide you with a smoother, more uniform surface and are particularly suitable for products that need a fine appearance or require subsequent surface treatment, such as painting or anodizing.

Optional Finishes For Casting Aluminum Parts

Spraying or painting

A specific coating or spraying process is used to form a protective film on the surface of an aluminum casting or to add aesthetic appeal. This method improves the surface’s corrosion resistance, abrasion resistance, or aesthetics.

Anodizing

Aluminum castings are placed in an acidic solution containing an electrolyte, and then an oxide layer is formed by applying an electric current. This oxide layer not only improves the hardness and corrosion resistance of the aluminum surface but also provides the appearance of different colors.

Mechanical Polishing

Improve the roughness of the surface of aluminum castings by using a mechanical grinding or polishing process to make it smoother and more uniform. This improves the appearance and gloss of the surface.

Sandblasting

Using high-pressure air to spray grit onto the surface of aluminum castings to remove surface oxidation layers, dirt, etc., thereby improving surface quality.

Electroplating

A layer of metal or alloy, such as nickel, chromium, or copper, is plated on the surface of an aluminum casting to improve its corrosion resistance, hardness, and appearance.

Common Applications of Cast Aluminum

Automotive industry

Engine parts (e.g., cylinder heads, crankcases, pistons), gearbox housings, brake system parts, suspension system parts, etc.

Aerospace

Structural parts for airplanes and rockets, engine parts, turbine blades, aircraft casings, etc.

Electronics

Manufacturing of components such as housings, heat sinks, and connectors for electronic products, such as computer housings, cell phone housings, and heat sinks.

Industrial machinery

Various mechanical parts, such as pump housings, valves, machine tool parts, pressure vessels, etc.

How long does cast aluminum last?

Aluminum castings have a long service life and can even be used indefinitely if it is used in an ideal environment, which, of course, requires you to maintain and inspect it regularly.

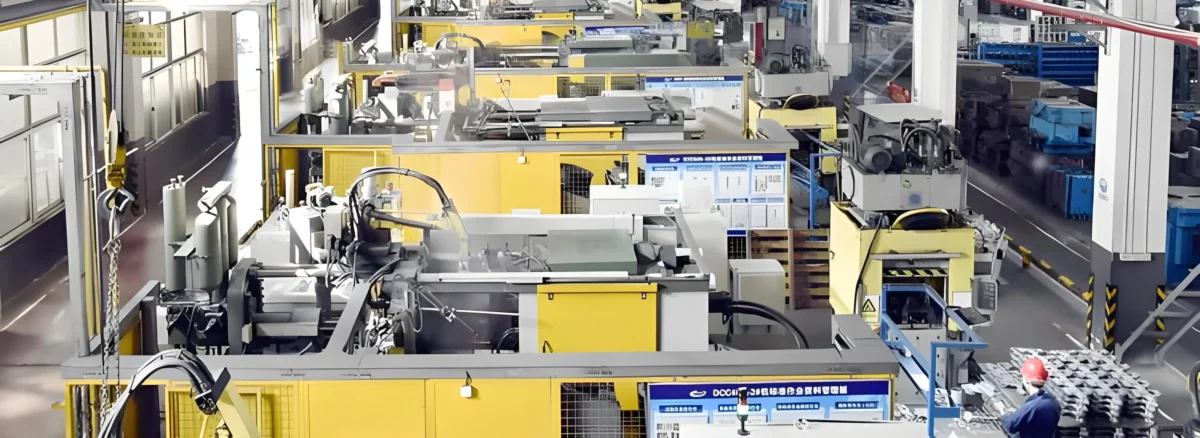

EVERGREEN’s cast aluminum technology

At EVERGREEN, we have advanced aluminum casting technology and rich production experience, we can provide you with professional service and high quality, high performance aluminum castings. We can also save costs for your project and realize a win-win situation. We have sand casting, die casting, precision casting, and other casting processes to meet all your needs.

With our experienced team of technicians, we are able to provide you with customized solutions, whether it’s a small part or a large component. From drawing design to finished product shipment, it’s no problem.

RFQ

Is cast aluminum heat-resistant?

Cast aluminum is known to have good heat resistance, but the exact degree of heat resistance depends on the alloy composition of the casting material and the design of the casting. Some cast aluminum alloys are highly heat resistant but may deform or even fail at extreme temperatures.

What is the tensile strength of cast aluminum?

The tensile strength of cast aluminum also depends on the casting alloy. Generally, the tensile strength of cast aluminum ranges from 150 to 300 MPa, but the tensile strength of specific alloys will vary.

Can cast aluminum be used for 3D printing?

Cast aluminum can be manufactured by 3D printing, which is now a mature technology. By using metal additive manufacturing techniques such as selective laser melting or electron beam melting, aluminum powder can be melted layer by layer and sintered into a part of the desired shape. And EVERGREEN can also provide this service for you.

Is cast aluminum pure aluminum?

Cast aluminum is generally not pure aluminum but an aluminum alloy. It is a material made by alloying aluminum with other elements (e.g., silicon, copper, magnesium, etc.) that can alter the properties of pure aluminum, such as strength, hardness, and corrosion resistance.