Why Weld Aluminum?

In the current industrial world, aluminum and aluminum alloys are widely used in many fields, such as automotive, railroad, aerospace, and communications, due to their lightweight, high hardness, high corrosion resistance, and good electrical and thermal conductivity.

Aluminum applications in many areas, according to the different needs of use, it is inevitable that there will be a variety of different processing processes, such as casting, forging, welding, machining, etc., and in the many aluminum processing technologies, welding is a more difficult one. However, many application areas have a great demand for aluminum welding, so aluminum welding is a necessary process for many industries.

Characteristics of Aluminum

As the saying goes, know your enemy and know yourself. So before you do aluminum welding, you need to understand the properties of aluminum. In the end, because of the characteristics that cause aluminum welding to be so difficult, only to understand these, you will be in the welding process to note these problems and reduce the chances of defective products in the aluminum welding process.

For example, the melting point of aluminum, the melting point of alumina, and thermal conductivity are all things you need to know and apply in practice.

Why Welding Aluminum is Challenging

The reason why aluminum welding is so difficult is due to its unique physical and chemical properties, next I will combine the unique properties of aluminum metal in detail why aluminum welding is so difficult.

Oxidation

When aluminum metal is exposed to air, it will quickly an air oxidation reaction on the surface the formation of a layer of dense aluminum oxide film; the film’s melting point of up to 2050 ° C, far higher than the melting point of aluminum metal 660 ° C.

If you don’t get rid of the aluminum oxide layer on the surface of the weld channel when you weld, it will be difficult for the current during welding to break it through, which will lead to poor weld quality, inclusions in the weld, and other problems.

It is also important to note that welding should be done within two hours of removing the oxide layer, otherwise the oxide layer will re-generate.

Porousness

During the welding process, aluminum melts into liquid aluminum due to high temperatures, at which point it easily absorbs hydrogen. As the liquid aluminum cools, the absorbed hydrogen will slowly precipitate out, forming tiny voids and bubbles in the weld. These small bubbles affect the integrity of the weld, causing the weld to fail and crack under pressure or stress.

You can minimize the appearance of these voids and bubbles and improve the quality of your weld by keeping the weld area dry and clean and using a higher-purity shielding gas.

Impurities

If your welding area, welding equipment or storage of aluminum is not clean, then you need to be aware of oil, stains, debris, corrosion, etc. that may appear on the surface of the aluminum while welding, all of which can directly affect the quality of the welded aluminum, causing impurities to be mixed in the weld, resulting in an unattractive, non-durable weld.

Thickness Variations

In the welding of aluminum will often encounter will be different thicknesses of aluminum plate welding together, when encountered in this case must be very tricky, if a piece of thick aluminum plate and thin aluminum plate welding together, the application of the current is too high then may be thin aluminum plate will be pierced, if the current is too low then can not achieve the effect of welding.

This problem requires you to have enough welding experience and skill to adjust the current to the optimum. Another way is to grind the weld of thick aluminum plate and let it weld with less current later.

Hot Cracking

In the welding is you may encounter this problem, that is, when the welding is good, wait until the aluminum parts cooled, there will be cracks, this is because the welding temperature is too high to cause the aluminum soften, can not meet the mechanical requirements of the weld, the weld will appear inside the shrinkage holes and cracks; of course, if the welding temperature is too low it will reduce the weld’s strength and plasticity, but also prone to cracks.

When you encounter this problem, you need to control the cooling rate; too fast or too slow will increase the probability of cracks in the weld.

Thermal Conductivity

As we all know, due to the characteristics of aluminum, its thermal conductivity is much higher than other metals, which will lead to the process of welding aluminum heat will be quickly dispersed to the surrounding area, the welding temperature can not be maintained in the appropriate range, which will lead to poor fusion of the weld.

This is where you need to increase the heat output and control the heat precisely, but be careful that the heat crack is not too high or you will melt through the aluminum.

Thermal Expansion

Due to the high coefficient of thermal expansion of the aluminum metal, the aluminum parts will expand significantly due to heat during the welding process, which will lead to problems such as deformation or stress concentration in the weld channel.

This requires you to take some proper measures when welding, such as preheating the aluminum parts, planning the welding sequence reasonably, and controlling the welding speed.

Things to Note When Welding Aluminum

There are many unexpected problems that you can encounter in welding that can lead to failure or even injury, but there are some problems that we can prevent ahead of time to avoid them from occurring during the welding process.

Cleanse

You need to avoid stained or oxidized aluminum. If you weld with aluminum that has not been cleaned, then the oil, stains, and oxidation on the surface will directly affect the quality of your weld.

However, you also need to use proper cleaning methods such as sanding and chemical cleaning to ensure that the surface of the aluminum piece is clean.

Welding Environment

The welding environment is also an area you need to pay attention to, keeping it dry and free of wind. If it is windy, the shielding gas will be blown away, which will absorb hydrogen and cause small bubbles during welding; while a humid environment will affect the quality of welding. Of course, a dust extraction system is also essential to protect the environment.

Safety Measures

This is an important item for your health, so make sure you wear protective equipment to protect your body when you are about to weld. When you weld aluminum, harmful fumes and strong UV radiation are produced, which can cause irreversible damage to your body. Welding masks, gloves, protective clothing and fume extraction equipment are essential.

Testing and Inspection

After successful welding, you need to carry out some necessary inspections on the product, such as appearance, integrity, internal structure (ultrasonic flaw detection), etc.

This is responsible for the product as well as the customer, and can help you improve product quality, increase customer satisfaction, and help your business tremendously in the future.

Training and Technical Updates

Whether you are a beginner or a seasoned expert, it is important to keep a lifelong learning heart. Times are advancing and welding techniques and methods are breaking through, and you need to stay up to date with the latest technology that can help you improve the quality and efficiency of your welds.

Types of Aluminum Welding

There are many processes that can weld aluminum, they all have their own strengths, the next to take you a detailed understanding of the advantages and disadvantages when they are used to weld aluminum, but also to help you choose the most suitable for your aluminum welding process.

Gas Tungsten Arc Welding (GTAW) / TIG

Advantages

- TIG welding produces clean, high-quality welds and is suitable for use on aluminum products that require high strength and appearance quality.

- If you’ve ever used TIG welding, you’ll find that it allows for precise heat output and molten pools and is well-suited for welding thin plates and complexly shaped aluminum parts.

Disadvantages

- TIG welding is slow and not well suited for high-volume production.

- Because TIG is more difficult to operate, it requires a high level of proficiency from the welder, and it has a higher cost of equipment.

Gas Metal Arc Welding (GMAW) / MIG

Advantages

- MIG welding is simpler, faster and requires less skill from the welder, so he is more suitable for automated mass production.

- Unlike TIG, it is more suitable for welding thicker aluminum plates and is mainly used for structural welding.

Disadvantages

- The quality of MIG welding is not as high as that of TIG, especially in the appearance of the weld, and it produces more spatter during welding, which needs to be cleaned up.

- Due to its high heat input, it creates a heat affected zone leading to deformation of the aluminum part and requires constant observation to control its parameters.

Resistance Welding and Laser Beam Welding

Advantages

- Resistance welding does not require the use of filler material, it saves you welding costs and time, and also simplifies the welding process. Therefore it is very fast and can realize automated high volume welding, which can make your welding efficiency greatly improved.

- Resistance welding is a direct conversion of electrical energy into heat energy focused on the welding point, it is high energy utilization, small heat-affected zone, can effectively reduce the deformation of the workpiece.

Disadvantages

- Resistance welding has certain requirements on the thickness of the weld material, it is better when welding materials with a thickness of 3mm or less, but the welding effect is not good for thicker materials. And the strength of the weld is lower compared to fusion welding.

- Resistance welding has high current requirements when welding, which means it requires better power supply equipment or a specialized power supply for it.

Electron Beam Welding

Advantages

- E-beam welding works with a high depth of fusion, and it is possible to weld thicker aluminum, which can be welded in a single pass. Due to its high depth of fusion, the strength of the weld is almost close to that of the base material.

- E-beam welding is very concentrated in the heat input, and the heat affected zone is very small, which reduces the number of defective products Others can accurately control the position and heat input, which is suitable for welding complex shapes of aluminum parts.

- At the same time, electron beam welding is highly automated and suitable for mass production.

Disadvantages

- E-beam welding equipment is costly and can be considered if you have a large value-added product or if the demand for your product is high; and it is a complex piece of equipment that is costly to maintain and requires specialized personnel to perform maintenance operations.

- E-beam welding requires a high degree of cleanliness on the surface of aluminum parts, otherwise welding defects will easily appear; it may not be as effective as other welding methods when facing some thin plates or other aluminum alloys.

The Best Way to Weld Aluminum

Above we have learned the advantages and disadvantages of each process that can be used to weld aluminum, and next, based on our practical experience, we will explain which process is the most suitable for welding aluminum, taking into account all aspects.

In fact, each different process has its own unique advantages, but we combined with the thickness of the weldable material, welding position, yield, quality, cost and other factors to comprehensively judge, argon arc welding (TIG) is the most appropriate.

TIG welding produces high quality welds and allows precise control of heat input, and we believe it is one of the most suitable processes for welding aluminum, especially when quality and appearance are important.

Although it is slower to weld and more difficult to work with, we feel that these drawbacks are fully offset by the long-term benefits of high quality and good looks.

Choosing the Correct Filler Metal (Welding Wire)

When welding aluminum, it is important to choose the correct wire. Otherwise, you will experience poor weld quality, uneven welds, cracks, porosity, and many other problems. Here’s what you want to take into consideration when choosing your welding wire:

Base Material Type

Different aluminum and aluminum alloys have different properties and you need welding wire that matches the base material.

- 1xxx Series (Pure Aluminum): Usually 1100 or 4043 wire is used.

- 2xxx Series (Aluminum-Copper Alloys): Usually 2319 or 4043 wire is used, but due to the poor weldability of the 2xxx series, preheating and post-processing are usually required.

- 3xxx Series (Aluminum-Manganese Alloys): Typically 4043 or 4943 wire is used.

- 4xxx Series (Aluminum-Silicon Alloys): Typically 4043 or 4047 wire is used.

- 5xxx Series (Aluminum-Magnesium Alloys): Typically 5356 or 5183 wire is used.

- 6xxx series (aluminum-magnesium-silicon alloys): Typically 4043, 4943 or 5356 wire is used.

- 7xxx Series (Aluminum-Zinc Alloys): Usually 2319 or 5356 wire is used, preheating is required before welding.

Welding Performance

- Fluidity: The fluidity of the wire directly affects the formation and appearance of the weld, such as high silicon content of the wire (such as 4043), its fluidity is very good, and suitable for welding complex shapes or thin plate.

- Crack sensitivity: the sensitivity of the wire to cracking varies, such as silicon-based wire (4043) is not sensitive to cracking, not easy to crack, and magnesium-based wire (5356) is more sensitive to thermal cracking easy to crack.

Weld Strength

The choice of wire will have a direct impact on the mechanical properties of the weld, such as strength, ductility and corrosion; if you require a high-strength weld then you need to choose a wire that matches the strength of the base material, if you want to weld alloys of the 5xxx and 6xxx series which have high strength requirements then you need to choose 5356 wire.

Common Filler Metals

- 4043: It contains 5% silicon, has good flow and low crack sensitivity and is suitable for most 1xxx, 3xxx, 4xxx and 6xxx series aluminum alloys.

- 5356: Contains 5% magnesium for 5xxx and 6xxx series aluminum alloys with high strength and good corrosion resistance, but high crack sensitivity.

- 4943: An improved silicone-based wire with higher strength and better flow than 4043 for 6xxx series aluminum alloys.

- 2319: Contains 6.3% copper and is dedicated to the 2xxx series of aluminum alloys for high strength and high temperature applications.

9 Tips for Welding Aluminum

With more than 20 years of welding experience, we have encountered a lot of problems and solved a lot of problems, and we would like to share with you the 9 tips for welding aluminum that we have accumulated and summarized over the years, and we believe that it will definitely help you.

Preheat the Metal

When you start to cool down after welding, the temperature of the weld will be quickly dispersed around, which will make the weld cool faster, easy to crack, become brittle, and fail to achieve the expected hardness.

To avoid this, you can preheat the aluminum part as a whole to about 150°C before welding, especially for thicker sections, so that the cooling after welding is slower and controlled, helping to reduce cracking and distortion of the weld.

You can use a propane or oxyacetylene torch to heat it, and it’s important to note that it must be heated evenly, and it should not be over-heated either, or it will affect the mechanical properties of the aluminum and cause it to become brittle.

Control the Heat

Because the melting point of aluminum is much lower than that of steel, iron and other metals, so please be sure to control the temperature when welding, otherwise the aluminum parts are very easy to be burned through, even if it is not less through, the temperature is too high, it is easy to make the material deformed.

That’s why you need to know the melting points of the various different aluminum and aluminum alloys and set the temperature best suited for welding in relation to their thickness.

Use a Faster Travel Speed

When welding aluminum, the welding speed should be faster than when welding steel. Increasing the welding speed prevents overheating and burn-through; in fact, welding aluminum is all about fast, consistent welding. This also helps the weld look good and reduces porosity.

Proper Welding Angle

For TIG and MIG, your torch should ideally be tilted 10-15 degrees in the direction of the weld. This tip helps the shielding gas cover the weld path better and reduces contamination from the outside world, and the proper weld angle also allows for enough penetration to form a good weld path.

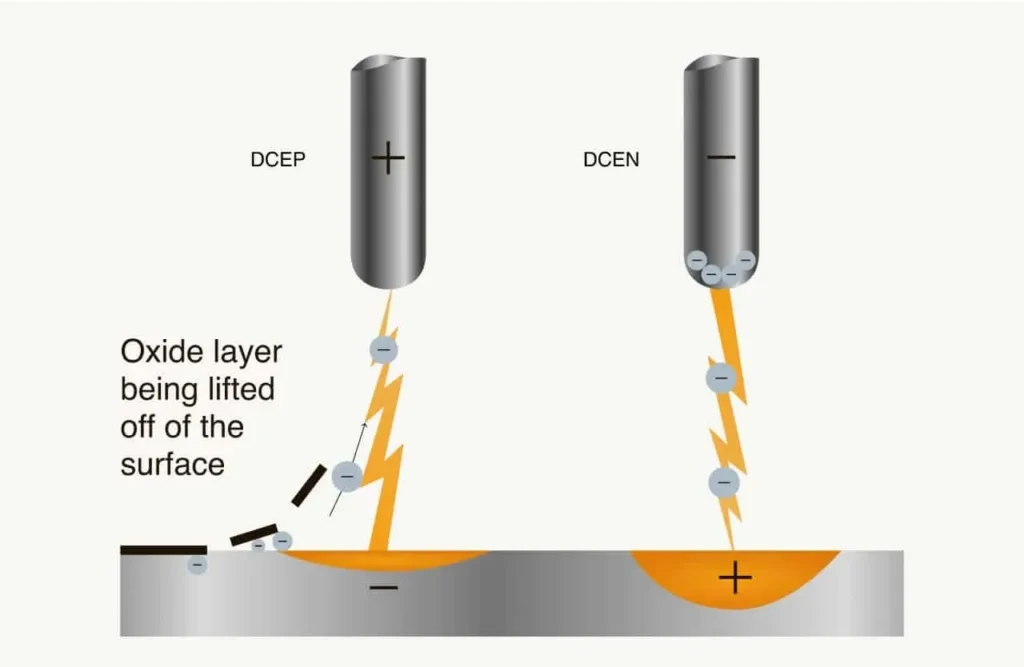

Use Alternating Current (AC) for TIG

However, if you use alternating current (AC) when TIG welding, you will find that the weld is clean and strong, because AC removes the oxide layer on the surface of the aluminum part and provides the heat needed for welding.

The cleaning action occurs during the positive electrode (DCEP) cycle, while the negative electrode (DCEN) cycle provides penetration and fusion.

Use the Correct Tungsten for TIG

When TIG welding aluminum, you can choose to use pure tungsten or zirconium tungsten as the electrode for welding. Using them as the electrode is not only resistant to contamination but also better stabilizes the arc.

If you sharpen the tip of the tungsten to a spherical shape to use for welding, this creates a more stable current.

Use a Spool Gun for MIG

If you use a spool gun when welding, you will find that it dramatically changes your welding process by ensuring smooth wire feed and ensuring consistent welds. It greatly solves difficult wire feeding situations and also prevents problems such as wire tangling.

Using a Push Technique for MIG

When MIG welding aluminum, you can use the push technique. Pushing the torch away from the molten pool helps improve gas coverage and depth of fusion. The technique also helps reduce contamination and produces cleaner, more visually appealing welds.

End the Weld Correctly

Once you have completed the weld, you need to gradually reduce the heat and fill the crater at the end of the weld. This process, often referred to as “puddle filling,” helps prevent crater cracking, which is common in aluminum welding.

In addition, a slight back-off technique is used to briefly reverse the direction of travel at the end of the weld to ensure a smooth and filled end joint.

Summary

In conclusion, welding aluminum is a complex and challenging technique that requires a high level of experience, skill and tools, but you can use this article in conjunction with practice to take some precautions that can effectively avoid common aluminum welding problems.

This guide provides a comprehensive overview of all aspects of aluminum welding, from preparation to specific techniques to solutions to common problems, and is designed to help welders improve the quality and efficiency of their welds. Both novice welders and seasoned professionals can benefit from this guide.