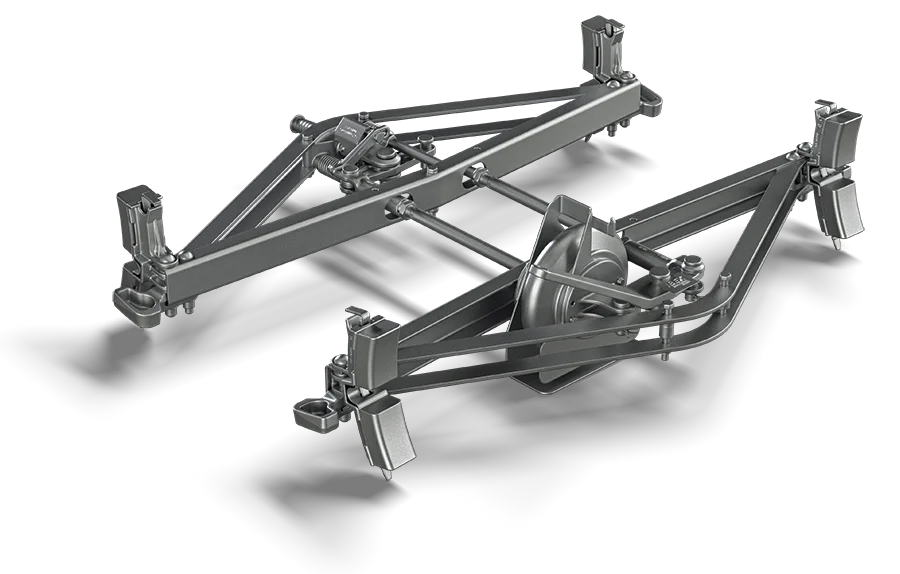

Track wheels can ensure the long-term stable operation of your equipment in harsh environments. The wheels produced by EVERGREEN are made of high-strength alloy steel, which is strong and durable and not easy to be corroded. The unique surface treatment can reduce the wear and tear of the wheels when you use them.

We have also optimized the shape of the rim to not only reduce friction but also prevent derailment. From pulleys for railroad tracks to train wheels, you can choose from a variety of different types, sizes and materials for.

EVERGREEN railway wheels are made of high-quality materials and manufactured using advanced casting techniques. They are highly wear- and corrosion-resistant and have a high load-bearing capacity.

Our rail wheels can play an important role in many industries and of course can also save more costs for your project.

EVERGREEN track wheels generally use high-strength alloys containing elements such as carbon, manganese, chromium and nickel to improve the strength and load-bearing capacity of the wheels. Of course, the materials we use have also been specially treated to be corrosion-resistant and heat-resistant. They are suitable for working in many different environments.

We have designed the rail wheels with heavy use in mind. Our wheels undergo a special surface treatment that creates a tough coating on the surface, which can effectively resist the wear and tear caused by heavy use.

This is a must. We have strict incoming material inspection and process control when manufacturing rail wheels. We also test the finished products for dimensional accuracy, performance, etc., and attach detailed inspection reports.

Our production cycle for rail wheels is usually 4 to 6 weeks, although this also depends on the quantity of orders and customization requirements. If you place an urgent order, we can prioritize it based on production capacity to try to meet your needs.

Send us a message to get a personalized quotation with up-to-date prices or for

any other questions. Our team would be more than happy to get back to you ASAP.

We have been committed to innovation, product quality, and perfection for over 25 years.

Call Us at: +86 139 6969 0461

Sign up to get Newsletter and Industry Updates.