There are many welding methods for aluminum alloys, and various methods have different applications. In addition to traditional fusion welding, resistance welding, and gas welding methods, some other welding methods (such as plasma arc welding, electron beam welding, vacuum diffusion welding, etc.) can also easily weld aluminum alloys together.

The characteristics and application scope of common welding methods for aluminum alloys are shown in Table 1. It should be selected according to the grades of aluminum and aluminum alloys, the thickness of the weldment, the product structure, and the requirements for weldability.

Table 1 Characteristics and application scope of common welding methods for aluminum alloys

(1) Gas welding

The thermal power of the oxy-acetylene gas welding flame is low, and the heat is relatively dispersed, so the deformation of the weldment is large and the productivity is low. Preheating is required when welding thick aluminum weldments by gas welding. The weld metal after welding is not only coarse in grain and loose in structure, but also prone to defects such as alumina inclusions, pores, and cracks. This method is only used for welding repair of unimportant aluminum structural parts and castings with a thickness ranging from 0.5 to 10 mm.

(2) TIG welding

This method is welding under argon protection, the heat is relatively concentrated, the arc combustion is stable, the weld metal is dense, the strength and plasticity of the welded joint are high, and it the more widely used in the industry. TIG welding is a relatively complete welding method for aluminum alloys, but the TIG welding equipment is more complicated and should not be operated in outdoor conditions.

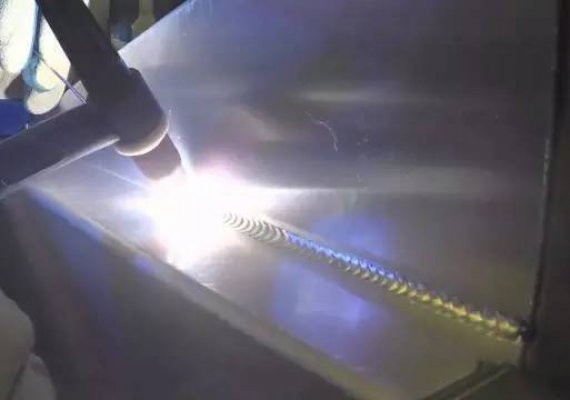

(3) Melting electrode argon arc welding

The arc power of automatic and semi-automatic melting electrode argon arc welding is large, the heat is concentrated, the heat affected area is small, and the production efficiency can be increased by 2 to 3 times compared with manual tungsten electrode argon arc welding. Pure aluminum and aluminum alloy plates with a thickness of less than 50mm can be welded. For example, welding aluminum plates with a thickness of 30 mm does not need to be preheated, and only the front and back layers can be welded to obtain a smooth surface and high-quality weld. Semi-automatic melting electrode argon arc welding is suitable for positioning welds, intermittent short welds, and weldments with irregular structural shapes. Semi-automatic argon arc welding torches can be used for convenient and flexible welding, but the diameter of semi-automatic welding wires is relatively small. The porosity of the weld is more sensitive.

(4) Pulse argon arc welding

1) Tungsten pulse argon arc welding

In this way, the stability of the low-current welding process can be significantly improved, and it is convenient to control the arc power and weld formation by adjusting various process parameters. The weldment has small deformation and small heat-affected zone and is especially suitable for thin plate, all-position welding, and other occasions, as well as the welding of forged aluminum, hard aluminum, super-hard aluminum, etc., which are highly sensitive to heat.

2) Melting electrode pulse argon arc welding

The applicable average welding current is small, the parameter adjustment range is large, the deformation of the weldment and the heat-affected zone is small, the productivity is high, and the porosity and crack resistance are good.

(5) Resistance spot welding, seam welding

It can be used to weld aluminum alloy sheets with a thickness of less than 4mm. For products with higher quality requirements, DC shock wave spot welding and seam welding machine welding can be used. Welding requires more complex equipment, high welding current, and high productivity, especially suitable for mass-produced parts and components.

(6) Friction stir welding

Friction stir welding is a solid-state joining technique that can be used for welding various alloy sheets. Compared with the traditional fusion welding method, friction stir welding has no spatter, no smoke, no need to add welding wire and shielding gas, and no pores and cracks in the joint. Compared with ordinary friction, it is not limited by shaft parts and can weld straight seams. This welding method also has a series of other advantages, such as good mechanical properties of the joint, energy saving, no pollution, and low requirements for pre-welding preparation. Due to the low melting point of aluminum and aluminum alloys, friction stir welding is more suitable.

Welding consumables for aluminum

(1) Welding wire

When welding aluminum alloys by gas welding, argon tungsten arc welding, etc., it is necessary to add filler wire. Aluminum and aluminum alloy welding wires are divided into two categories: homogeneous welding wire and heterogeneous welding wire. In order to obtain a good welded joint, the welding wire suitable for the base metal should be selected as the filler material considering the use requirements of the welded components.

The selection of welding wire should first consider the composition requirements of the weld, but also the mechanical properties, corrosion resistance of the product, rigidity, color, and crack resistance of the structure. Selecting a filler metal with a melting temperature lower than that of the base metal can greatly reduce the tendency for intergranular cracking in the heat-affected zone. For the welded joint strength of non-heat treated alloys, increase in the order of 1000 series, 4000 series, and 5s000 series.

5000 series welding wires containing more than 3% magnesium should be avoided in structures with operating temperatures above 65 °C, because these alloys are very sensitive to stress corrosion cracking, and stress corrosion cracking will occur in the above-mentioned temperature and corrosive environment. Using a wire with a higher alloy content than the base metal as the filler metal usually prevents the cracking tendency of the weld metal.

At present, most of the commonly used welding wires for aluminum alloys are standard grades of welding wires that are similar in composition to the base metal. In the absence of standard grades of welding wire, strips can be cut from the base metal instead. The more common welding wire is HS311, which has good liquid metal fluidity, small shrinkage during solidification, and excellent crack resistance. In order to refine the seam grains and improve the crack resistance and mechanical properties of the weld, a small amount of Ti, V, Zr, and other alloying elements are usually added to the wire as modifiers.

The problems that should be paid attention to when choosing aluminum alloy welding wire are as follows :

1) Crack susceptibility of welded joints

The direct factor that affects the crack susceptibility is the matching of the base metal and the welding wire. Selecting a weld metal with a melting temperature lower than that of the base metal can reduce the crack susceptibility of the weld metal and heat-affected zone. For example, when welding 6061 alloys with a silicon content of 0.6%, the same alloy is used as the weld, and the crack sensitivity is very high.

However, the ER4043 welding wire with a silicon content of 5% has good crack resistance due to its lower melting temperature than that of the 6061 alloy and higher plasticity during cooling. In addition, the weld metal avoids the combination of magnesium and copper because Al-Mg-Cu has a high crack susceptibility.

2) Mechanical properties of welded joints

Industrial pure aluminum has the lowest strength, 4000 series aluminum alloy is in the middle, and 5000 series aluminum alloy has the highest strength. Although aluminum-silicon welding wire has high crack resistance, the plasticity of silicon-containing welding wire is poor, so for joints that need plastic deformation processing after welding, silicon-containing welding wire should be avoided.

3) Performance of welded joints

The choice of filler metal depends not only on the base metal composition, but also on the geometry of the joint, the corrosion resistance requirements in service, and the appearance of the weldment. For example, welded containers for storing hydrogen peroxide require high-purity aluminum alloys in order to provide good corrosion resistance to the container or to prevent contamination of the container by the stored product. In this case, the filler metal must be at least as pure as the base metal.

(2) Welding rod

See Table 2 for the model, specification, and use of aluminum alloy electrodes. The chemical composition and mechanical properties of the aluminum alloy electrodes are shown in Table 3.

Table 2 Types (brands), specifications, and uses of aluminum and aluminum alloy electrodes.

Table 3 Chemical composition and mechanical properties of aluminum and aluminum alloy electrodes

(3) Protective gas

Inert gases for welding aluminum alloys include argon and helium. The technical requirements of argon are Ar>99.9%, oxygen <0.005%, hydrogen <0.005%, moisture <0.02mg/L, nitrogen <0.015%. Oxygen and nitrogen increase, both deteriorate the cathode atomization. Oxygen > 0.3% will aggravate the burning loss of the tungsten electrode, and if it exceeds 0.1%, the surface of the weld will be dull or black.

In tungsten argon arc welding, pure argon gas is used for AC and high-frequency welding, which is suitable for large thickness plates; Ar+He or pure Ar is used for DC positive polarity welding.

When melting electrode argon arc welding, when the plate thickness is less than 25mm, pure Ar is used. When the plate thickness is 25 to 50 mm, an Ar+He mixed gas added with 10% to 35% Ar is used. When the plate thickness is 50 to 75 mm, it is advisable to use an Ar+He mixed gas with 10% to 35% or 50% He added. When the plate thickness is greater than 75mm, it is recommended to add 50% to 75% He Ar+He mixed gas.

The aluminum alloy welding process

1 Gas welding of aluminum alloys

The thermal efficiency of oxygen-acetylene gas welding is low, the heat input of welding is not concentrated, flux is required when welding aluminum and aluminum alloys, residues need to be removed after welding, and the quality and performance of joints are not high. Because the gas welding equipment is simple, no power supply is required, and the operation is convenient and flexible, it is often used for welding aluminum alloy components with low-quality requirements, such as thin plates and small parts, as well as repairing welding aluminum alloy components and aluminum castings.

(1) Joint form of gas welding

When gas welding aluminum alloys, it is not suitable to use lap joints and T-shaped joints, which are difficult to clean the residual flux and welding slag flowing into the gap, and butt joints should be used as much as possible. In order to ensure that the weldment is welded without collapse and burn-through, a backing plate with grooves can be used. The backing plate is generally made of stainless steel or pure copper. Welding with a backing plate can obtain good reverse forming and improve welding productivity.

(2) Selection of gas welding flux

During gas welding of aluminum alloys, in order to make the welding process go smoothly and ensure the quality of the weld, it is necessary to add flux to remove the oxide film and other impurities on the aluminum surface during gas welding.

Gas welding flux (also known as gas flux) is a flux in gas welding. Its main function is to remove the oxide film formed on the surface of aluminum during gas welding, improve the wetting performance of the base metal, and promote the acquisition of dense weld structures. Flux must be used for gas welding of aluminum alloys. Generally, the flux is directly sprinkled on the groove of the workpiece to be welded before welding or is added to the molten pool by dipping it on the welding wire.

Aluminum alloy flux is the chloride salt of potassium, sodium, calcium, lithium, and other elements. It is a powder compound prepared by sieving after crushing. For example, aluminum cryolite (Na3AlF6) can melt alumina at 1000 °C, and potassium chloride can convert refractory alumina into fusible aluminum chloride. This flux has a low melting point and good fluidity, and can also improve the fluidity of the molten metal and make the weld well-formed.

(3) Selection of welding tip and flame

Aluminum alloys have strong oxidizing and gettering properties. During gas welding, in order to prevent the aluminum from being oxidized, a neutral flame or a weak carbonization flame (a carbonized flame with excess acetylene) should be used, so that the aluminum molten pool is placed under the protection of a reducing atmosphere without being oxidized. It is strictly forbidden to use an oxidizing flame because the use of an oxidizing flame with strong oxidizing property will strongly oxidize the aluminum and hinder the welding process; and if there is too much acetylene, free hydrogen may dissolve into the molten pool, which will cause the seam to generate pores and make the welding seam lose.

(4) Positioning welds

In order to prevent the size and relative position of the weldment from changing during welding, spot welding is required before the weldment is welded. Due to the large coefficient of linear expansion of aluminum, the fast thermal conductivity, and the large heating area of gas welding, the tack weld should be denser than that of steel parts.

The filler wire used for tack welding is the same as that used for production welding. Before tack welding, a layer of aerosol should be applied in the weld gap. The flame power of tack welding is slightly larger than that of gas welding.

(5) Gas welding operation

When welding steel materials, the heating temperature can be judged by the color change of the steel. But when welding aluminum, there is no such convenient condition. Because the aluminum alloy has no obvious change in color during heating from room temperature to melting, it is difficult for the operator to control the welding temperature. However, the timing of welding can be grasped according to the following phenomena:

1) When the surface of the heated workpiece changes from bright white to dull silver-white, the oxide film on the surface is wrinkled, and the metal fluctuates at the heating place, it indicates that the melting temperature is about to be reached, and welding can be applied;

2) Use the end of the welding wire dipped in flux and the place to be heated when the welding wire and the base metal can be fused, that is, the melting temperature is reached, and welding can be performed;

3) When the edge of the base metal falls down, the base metal reaches the melting temperature and can be welded.

Gas welding of thin plates can be done by the left welding method, the welding wire is located in front of the welding flame, this welding method because the flame points to the unwelded cold metal, part of the heat is dissipated, which is beneficial to prevent the molten pool from overheating, the growth of metal grains in the heat-affected zone and burn through. If the thickness of the base metal is greater than 5mm, the right-hand welding method can be used. In this method, the welding wire is behind the welding torch, and the flame is directed to the welding seam so that the heat loss is small, the penetration depth is large, and the heating efficiency is high.

When gas welding thin parts with a thickness of less than 3mm, the torch inclination angle is 20-40°; when gas welding thick parts, the torch inclination angle is 40-80°, and the angle between the welding wire and the torch is 80-100°. Aluminum alloy gas welding should try to weld the joints at one time, and not deposit the second layer because the slag inclusion in the weld will be caused when the second layer is deposited.

(6) Post-weld treatment

The corrosion of the aluminum joint by the residual flux and slag on the surface of the gas welding seam is one of the reasons for the damage of the aluminum joint in future use. Within 1 to 6 hours after gas welding, the residual flux and slag should be cleaned to prevent corrosion of the weldment. The cleaning process after welding is as follows.

1) After welding, immerse the weldment in a hot water tank at 40-50°C. It is best to use flowing hot water to brush the welding seam and the places where the residual flux and slag remain near the welding seam until it is cleaned up.

2) Immerse the weldment in a nitric acid solution. When the room temperature is above 25°, the concentration of the solution is 15% to 25%, and the immersion time is 10 to 15 minutes. When the room temperature is 10~15℃, the concentration of the solution is 20%~25%, and the immersion time is 15min.

3) Immerse the weldment in the tank of flowing hot water (temperature is 40-50℃) for 5-10min.

4) Rinse the weldment with cold water for 5 minutes.

5) Dry the weldment naturally, or dry it in a drying oven or dry it with hot air.

2. TIG welding of aluminum alloys (TIG welding)

Also known as tungsten inert gas shielded arc welding, a large amount of heat generated by the arc formed between the tungsten electrode and the workpiece is used to melt the part to be welded, and a filler wire is added to obtain a firm welded joint. TIG welding of aluminum uses its “cathode atomization” feature to remove the oxide film by itself. The tungsten electrode and the seam area are shielded and protected by the inert gas ejected from the nozzle to prevent the reaction between the weld seam area and the surrounding air.

The TIG welding process is most suitable for welding thin plates with a thickness of less than 3mm, and the deformation of the workpiece is significantly smaller than that of gas welding and hand arc welding. The AC TIG welding cathode has the cleaning effect of removing the oxide film, and it can be used without flux, which avoids the corrosion of the joint by residual flux and slag after welding. The form of the joint can be unlimited, the welding seam is well-formed and the surface is bright.

The scouring of the welding area by the argon flow accelerates the cooling of the joint, improves the structure and performance of the joint, and is suitable for all-position welding. Because no flux is used, the requirements for pre-welding cleaning are stricter than other welding methods.

The more suitable process methods for welding aluminum alloys are AC TIG welding and AC pulse TIG welding, followed by DC reverse TIG welding. Usually, when welding aluminum alloys with AC, the best combination of current carrying capacity, arc controllability, and arc cleaning can be achieved, so most of the TIG welding of aluminum alloys uses AC power.

When DC positive connection is used (electrode is connected to the negative electrode), heat is generated on the surface of the workpiece, forming deep penetration, and a larger welding current can be used for electrodes of a certain size. Preheating is not required even for thick sections, and the base metal hardly deforms. Although DC reverse (electrode to positive) TIG welding method is rarely used to weld aluminum, this method has shallow penetration, arcing, and continuous welding or repair welding of thin-walled heat exchangers and similar components with a pipe thickness of 2.4 mm or less. It is easy to control, and the arc has the advantage of a good purification effect.

(1) Tungsten electrode

The melting point of tungsten is 3410 ℃, which is the metal with the highest melting point. Tungsten has a strong electron emission ability at high temperatures. After adding trace oxides of rare earth elements such as thorium, cerium, and zirconium to the tungsten electrode, the electron work function is significantly reduced, and the current carrying capacity is significantly improved. During TIG welding of aluminum alloys, the tungsten electrode as an electrode mainly plays the role of conducting current, igniting the arc, and maintaining the normal combustion of the arc. Commonly used tungsten materials are divided into pure tungsten, thorium tungsten, and cerium tungsten.

(2) Welding process parameters

In order to obtain excellent weld formation and welding quality, the welding process parameters should be reasonably selected according to the technical requirements of the weldment. The main process parameters of aluminum alloy manual TIG welding are current type, polarity, current size, shielding gas flow, tungsten electrode extension length, distance from the nozzle to the workpiece, etc. The process parameters of automatic TIG welding also include arc voltage (arc length), welding speed, and wire feeding speed.

The process parameters are based on the material and thickness to be welded, first determine the diameter and shape of the tungsten electrode, the diameter of the welding wire, the shielding gas and flow rate, the diameter of the nozzle, the welding current, the arc voltage, and the welding speed, and then adjust the relevant parameters according to the actual welding effect until it is suitable for use. until requested.

The selection points of aluminum alloy TIG welding process parameters are as follows:

1) Nozzle aperture and protective gas flow

The nozzle aperture of aluminum alloy TIG is 5-22mm; the protective gas flow rate is generally 5-15L/min.

2) The extension length of the tungsten electrode and the distance from the nozzle to the workpiece

The extension length of the tungsten electrode is generally 5 to 6 mm for butt welds and 7 to 8 mm for fillet welds. The distance from the nozzle to the workpiece is generally about 10mm.

3) Welding current and welding voltage are related to plate thickness, joint form, welding position, and welder technical level.

In manual TIG welding, AC power is used, and when the welding thickness is less than 6mm aluminum alloy, the maximum welding current can be determined according to the formula I=(60~65)d according to the electrode diameter d. The arc voltage is mainly determined by the arc length, and it is generally reasonable to make the arc length approximately equal to the diameter of the tungsten electrode.

4) Welding speed

During TIG welding of aluminum alloys, in order to reduce the deformation, a faster welding speed should be used. Manual TIG welding is generally when the welder adjusts the welding speed at any time according to the size of the molten pool, the shape of the molten pool, and the fusion situation on both sides. The welding speed is generally unchanged.

5) Welding wire diameter

Generally determined by the plate thickness and welding current, the wire diameter is proportional to the relationship between the two.

1) Causes of stomata

The purity of argon gas is low or there is moisture or air leakage in the argon gas pipeline; the welding wire or the groove of the base metal are not cleaned before welding or are contaminated with dirt and moisture after cleaning; the welding current and welding speed are too large or too high Small; poor molten pool protection, unstable arc, too long arc, too long tungsten electrode sticking out, etc.

Preventive measures:

To ensure the argon pipeline, choose to carefully clean the welding wire and weldment, and weld in time after cleaning to prevent re-contamination. Update the gas supply pipeline, select the appropriate gas flow, adjust the extension length of the tungsten electrode; correctly select the welding process parameters. If necessary, a preheating process can be adopted, and a windshield device can be installed on the welding site to prevent wind flow on-site.

2) Causes of cracks

Improper selection of welding wire alloy composition; when the magnesium content in the weld is less than 3%, or the content of iron and silicon impurities exceeds the specification, the crack tendency increases; when the melting temperature of the welding wire is too high, it will cause liquefaction cracks in the heat-affected zone; structural design Unreasonable, the weld is too concentrated or the temperature of the heated area is too high, resulting in excessive joint restraint stress; high turbidity stays for a long time, the structure is overheated; the arc crater is not filled, and arc crater cracks appear.

Preventive measures:

The composition of the selected welding wire should be matched with the base metal; the arc ignition plate should be added or the current attenuation device should be used to fill the arc crater; the welding structure should be correctly designed, the welding seam should be arranged reasonably, and the welding seam should avoid the stress concentration point as much as possible, and the appropriate welding sequence should be selected. ; Reduce the welding current or increase the welding speed appropriately.

3) Causes of incomplete penetration

The welding speed is too fast, the arc length is too large, the gap of the weldment, the groove angle, and the welding current are too small, and the blunt edge is too large; the burrs on the edge of the workpiece groove and the dirt on the bottom edge are not removed before welding; The inclination is incorrect.

Preventive measures:

Correctly select the gap, blunt edge, groove angle, and welding process parameters; strengthen the cleaning of oxide film, flux, slag, and oil; improve operation skills, etc.

4) Causes of tungsten inclusion in welds

Caused by contact arc ignition; unreasonable selection of tungsten electrode tip shape and welding current, so that the tip falls off; filler wire touches the hot tungsten electrode tip and misuse of the oxidizing gas.

Preventive measures:

Use high-frequency high-voltage pulse arc ignition; according to the selected current, use a reasonable tungsten tip shape; reduce the welding current, increase the diameter of the tungsten electrode, and shorten the length of the tungsten electrode extension; update the inert gas; Contact with tungsten electrode, etc.

5) Causes of undercut

Too much welding current, too high arc voltage, uneven torch swing, too little filler wire, and too fast welding speed.

Preventive measures

Reduce the welding current and arc voltage, keep the torch swing evenly, and appropriately increase the wire feeding speed or reduce the welding speed.

3. Conventional repair welding process for castings

The defects of common aluminum alloy castings can be repaired and rescued by argon arc welding, and the effect of AC TIG welding is better.

When using the repair welding process to repair casting defects, in addition to the general practices mentioned above, such as cleaning the welding wire and the parts to be welded on the workpiece before welding, selecting reasonable welding wire materials, and selecting short arc and small-angle welding wires for welding and other points, In addition, there are many successful experiences for different defect types in practice that are worth learning, such as using low current welding as much as possible;

The alloy composition of the welding wire during repair welding is higher than that of the base metal so that the burnt alloy can be supplemented during the repair welding process so that the composition of the weld seam is consistent with that of the base metal; crack prevention holes are drilled at both ends before repair welding of castings with crack defects; During welding, the part to be welded should be heated first, and the left welding method should be used to fill the wire to facilitate the observation of the melting of the weld. After the welding place is melted, the wire should be filled to form a fully wetted molten pool;

When the defect size is large, in order to improve the repair welding efficiency, a thin layer of surfactant (ATIG activator) can be applied to the surface of the welding position before traditional TIG welding. The metal flow in the molten pool changes, which increases the weld penetration. During AC TIG welding of aluminum alloys, a layer of SiO2 activator is applied to the weld surface to change the weld penetration, reduce the preheating procedure and reduce the welding speed. difficulty.

concluding remarks

Welding and repair welding of aluminum alloys can usually be done by the convenient and low-cost TIG and MIG argon arc welding methods. When using new aluminum alloy welding processes such as high-energy beam welding and friction stir welding, problems such as alloy element burning, joint softening, and welding deformation can be effectively avoided.

When the conventional repair welding method is used for repairing defects of aluminum alloy castings, in order to avoid welding defects, attention should be paid to cleaning before welding, selecting reasonable wire fillers, and correct welding process specifications, usually, AC TIG repair welding should be used.

When the casting defects are special and conditions are met, special repair welding methods can be used in combination with the actual situation in order to improve the repair welding quality of aluminum alloy castings.

Like this page? Share it with your friends!