A brief description of sheet metal and an overview of the industry:

1. With the development of automobiles, communication, IT, and daily hardware manufacturing, sheet metal processing has become more and more popular, and it becomes more necessary to understand sheet metal processing.

2. The operation of making metal sheets, profiles, and pipes into parts with a certain shape, size, and precision by manual or mechanical methods is called sheet metal processing; it is widely used in the production of ventilation, and air conditioning pipes, and their components.

3. Most of the sheet metal parts are made of metal sheets and pipe fittings. Because of its lightweight, high strength, rigidity, arbitrary complex shape, low material consumption, no need for machining, and smooth surface, it is widely used in daily life. It is widely used in industrial and industrial production, such as buckets, basins, ventilation pipes, material conveying pipes, automobile cover parts processing, etc. In addition, it can also be used in automobile exterior repair and other work.

4. Metal sheet processing, usually refers to cutting, bending, calendering, rummaging, and other methods. Generally speaking, the process of using molds to complete various deformation processes is called the sheet metal stamping process, and the process of forming sheet metal by hand or machinery is called sheet metal processing.

Sheet metal material:

1. Electrolytic plate: SECC (N) (fingerprint resistant plate), SECC (P), DX1, DX2, SECD (stretch plate). Material hardness: HRB50°+-5°, tensile plate: HRB32°~37°

2. Cold-rolled sheet: SPCC, SPCD (stretch sheet), 08F, 20, 25, Q235-A, CRS. Material hardness: HRB50°+-5°, tensile plate: HRB32°~37°.

3. Aluminum plate; AL, AL (1035), AL (6063), AL (5052), etc.

4. Stainless steel plate: SUS, SUS301 (302, 303, 304), 2Cr13 , 1Cr18Ni9Ti, etc.

5. Other commonly used materials are pure copper plate (T1, T2), hot-rolled plate, spring steel plate, galvanized plate, aluminum profile, etc.

Sheet metal processing technology:

Sheet metal processing technology can basically be divided into scribing, shearing, square folding, rounding (rolling), bending, seaming or welding, flange making an upper flange, and other processes. This section mainly introduces the processes of scribing, rolling, square bending, biting, and pipe bending.

1 dash

(1). most of the sheet metal parts are made of flat metal sheets, so the actual surface size of the sheet metal parts must be drawn into a plane figure on the metal sheet, this method is called unfolding and scribing.

(2). according to the unfolding properties of the surface of the component parts, it can be divided into two types: developable surface and non-developable surface.

(3) The surface of the part can be flattened on a plane without tearing or wrinkling. This surface is called a developable surface. The plane, cylindrical and conical surfaces are developable surfaces. If the surface of the part cannot be unfolded naturally and flattened on a plane, it is called a non-developable surface, such as the surface of a sphere, a ring, and a helical surface, etc. are all non-developable surfaces, and they can only be approximately unfolded.

2 sheet metal processing method

1), blanking:

Cutting is to cut the material into the required shape according to the unfolding. There are many methods of blanking, which can be divided into shearing, punching, and laser cutting according to the type of machine tool and working principle.

(1.1) Cutting – use scissors to cut out the desired shape. The accuracy can reach more than 0.2mm, mainly used for cutting strips or cutting clean materials.

(1.2) Punching and blanking – use a numerical control punch (NC) or ordinary punch for blanking. The accuracy of the two blanking methods can reach more than 0.1mm, but the former will have knife marks during blanking and the efficiency is relatively low, while the latter has high efficiency but high unit cost, which is suitable for mass production.

(1.2.1) When the CNC punching machine is blanking, the upper and lower molds are fixed, and the worktable is moved to punch the plate and process the required workpiece shape. There are mainly two types of CNC punching machines: Tailifu and AMADA.

(1.2.2) Ordinary punch presses use the blanking die to punch out the required shape of the material through the movement of the upper and lower dies. Ordinary punching machines generally must cooperate with shearing machines to punch out the required shape, that is, first use the shearing machine to cut the strips, and then use the punching machine to punch out the required shape of the material.

(1.3) Laser cutting – use laser cutting equipment to continuously cut the plate to obtain the required shape of the material. It is characterized by high precision and can process materials with very complex shapes, but the processing cost is relatively high.

2), forming:

Sheet metal forming is the main processing method in sheet metal processing. Forming can be divided into two types: manual forming and machine forming. Manual forming is often used as supplementary processing or finishing work and is rarely used. However, manual forming is still inseparable when processing some materials with complex shapes or prone to deformation. Hand forming is done using some simple fixtures. The following methods are mainly used: bending, edge laying, edge closing, arching, curling, and schooling.

What we mainly discuss here is machine forming: bending forming, and stamping forming.

(2.1) Bending and forming—fix the upper and lower molds on the upper and lower worktables of the folding bed respectively, and use the servo motor to drive the relative movement of the worktable, combined with the shape of the upper and lower molds, so as to realize the bending and forming of the plate. The forming accuracy of bending can reach 0.1mm.

(2.2) Stamping forming—Using the power generated by the motor to drive the flywheel to drive the upper mold, combined with the relative shape of the upper and lower molds, the plate is deformed to realize the processing and forming of the material. The precision of stamping can reach more than 0.1mm. Punches can be divided into ordinary punches and high-speed punches.

3) Connection of sheet metal

Ventilation pipes and components made of metal sheets can be connected by bite connections, rivet connections, welding, and other methods. This section mainly introduces snap connections.

The edge of two boards (or the two sides of a piece of material) is bent and pressed against each other. This connection method is called bite ( seam ). Sheet metal connection is to connect different materials together in a certain way, so as to obtain the required products. Sheet metal connection can be divided into welding, riveting, screw connection, and so on.

1. Bite connection

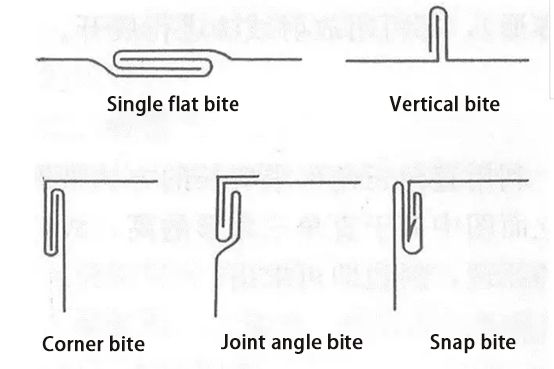

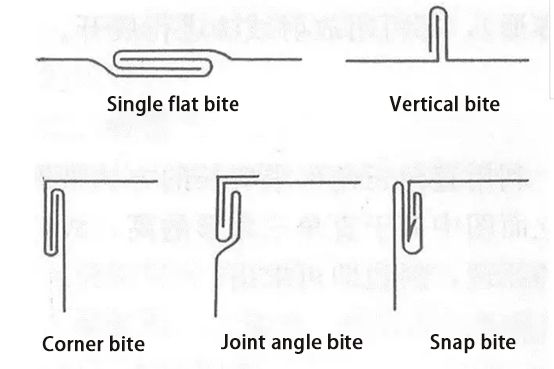

1). Type of bite

2 ) . Bite application

Various bites are mainly used in the following aspects:

(1) The single flat seam is used for the splicing seam of the plate, the longitudinal closing seam of the air duct, or the component.

(2) The single vertical bite is used for circular elbows, back-and-forth bends, and transverse seams of air ducts.

(3) Corner seams, joint corner seams, and snap-button seams are used for longitudinal closing seams of rectangular air ducts or components, as well as corner seams of rectangular elbows and tees.

2. Bite width and allowance

The width of the bite depends on the thickness of the pipe fittings to be made.

1 ) . The size of the bite allowance is related to the width of the bite, the number of overlapping layers, and the machinery used.

2 ) For a single flat seam, single vertical seam, and corner seam, the amount left on one plate is equal to the width of the seam, while the amount left on the other plate is twice the width of the seam. Therefore, the seam allowance That’s three times the bite width.

3 ) . For joint corner bites, leave an amount equal to the width of the bite on one plate, and three times the width of the bite on the other plate, for a total allowance of four times the width of the bite.

4 ) . The amount of bite should be left on both sides of the plate according to the needs.

1. hand bite

The manual bite process is as follows:

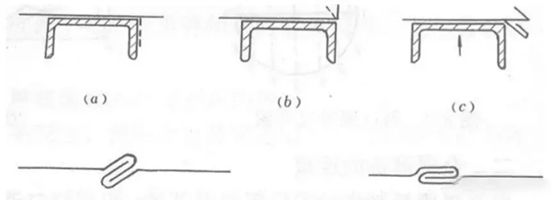

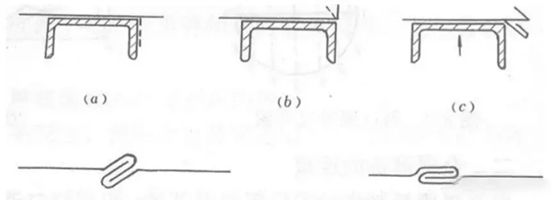

(1) Processing of single flat seam (pictured below) Place the sheet with a pre-drawn bending line on the channel steel so that the bending line of the buckle is aligned with the edge of the channel steel:

( 2 ) The seaming machines include linear seaming machines and elbow seaming machines, which can complete the seam forming of square, rectangular, round pipes, elbows, tees, and variable diameter pipes, and the seam shape is accurate. The surface is smooth, the size is consistent, and the productivity is high. It is widely used in the processing of air conditioners and ventilation pipes.

( 3 ) The process of the nip forming The mechanical nip is to make the plate pass through several pairs of rotating rollers with different groove shapes, so that the bending of the edge of the plate changes gradually from small to large, and is formed step by step.

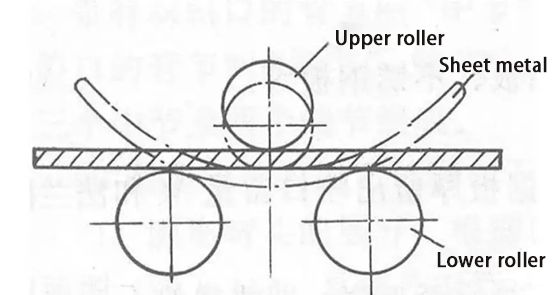

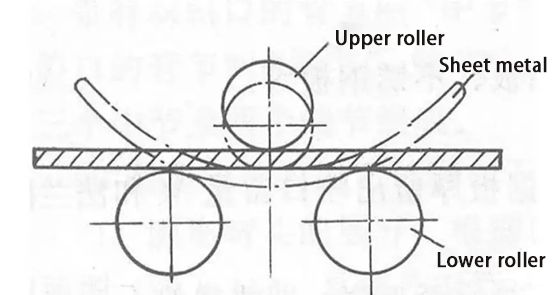

3. Rolling and bending of the sheet When making a circular air duct from the sheet, it is necessary to roll the sheet into a circle (bend). When making a rectangular air duct, the board needs to be folded into squares.

The bending of the sheet through the rotating roller, the method of bending the sheet is called bending, also known as rounding.

1 ) . The basic principle, basic principle of roll bending is shown in the figure. The sheet is placed on the lower roller, and the distance between the upper and lower rollers can be adjusted. When the distance is less than the thickness of the sheet, the sheet will be bent, which is called bending. If it is continuously rolled, the sheet will form a smooth curvature within the range it is rolled to (but the two ends of the sheet are still straight because they cannot be rolled, and must be eliminated when forming parts). So the essence of roll bending is continuous bending.

( 3.1 ) Welding can be divided into CO2 welding, Ar welding, resistance welding, etc.

( 3.1.1 ) CO2 welding processing principle: Use protective gas (CO2) to mechanically isolate the air from the molten metal to prevent oxidation and nitriding of the molten metal. It is mainly used for welding iron materials. Features: The connection is firm and the sealing performance is good. Disadvantages: It is easy to deform during welding. CO2 welding equipment is mainly divided into robot CO2 welding machines and manual CO2 welding machines.

( 3.1.2 ) Ar arc welding is mainly used for welding aluminum and stainless steel materials. Its processing principle and advantages and disadvantages are the same as CO2, and the equipment is also divided into robot welding and manual welding.

( 3.1.3 ) The working principle of resistance welding: using the resistance heat generated by the current passing through the weldment, the weldment is melted and heated to connect the weldment. The equipment mainly includes the Songxing series, Qilong series, etc.

( 3.2 ) Riveting can be divided into: pressure riveting connection and rivet connection, etc. Common riveting equipment includes a riveting machine, a riveting gun, and a POP riveting gun.

( 3.2.1 ) Pressure riveting connection is to press screws and nuts into the material so that it can be threaded to connect other parts.

( 3.2.2 ) Rivet connection is to use rivets to connect two parts together.

Surface treatment:

The decorative and protective effect of surface treatment on the surface of products is recognized by many industries. In the sheet metal industry, the commonly used surface treatment methods include electroplating, spraying, and other surface treatment methods.

1 ) Electroplating is divided into: galvanized ( color zinc, white zinc, blue zinc, black zinc), nickel plating, chrome plating, etc.;

It is mainly to form a protective layer on the surface of the material, which plays the role of protection and decoration;

2 ) There are two types of spraying: paint spraying and powder spraying. After the material is pre-treated, the paint is sprayed onto the surface of the workpiece with a spray gun and gas, and the paint forms a coating on the surface of the workpiece. After drying, it plays a protective role;

Manual pipe bending

In no-bending equipment or single-piece small batch production, the number of elbows is small, and it is uneconomical to make bending dies. In this case, manual bending is used. The main processes of manual bending include sand filling, scribing, heating, and bending.

1. When manually bending the pipe with sand filling, in order to prevent the deformation of the steel pipe section, the following main methods are adopted: the pipe is filled with fillers (quartz sand, rosin, and low-melting-point alloys, etc.). For larger-diameter steel pipes, and is generally used. Before filling the sand, plug one end of the steel pipe with a tapered cork, and there is an air outlet on the cork so that the air in the pipe can escape freely when heated and expanded. After filling the sand, the other end of the pipe is also plugged with a cork. The sand loaded into the steel pipe should be clean, dry, and compact.

For steel pipes with larger diameters, when it is inconvenient to use wooden stoppers, steel stopper plates can be used.

2. Scribe to determine the heating length of the steel pipe

3. Heating Charcoal, coke, gas, or heavy oil can be used as fuel for heating. The heating should be slow and uniform, and the heating temperature of ordinary carbon steel is generally around 1050 °C. Cold bending is used for stainless steel and alloy steel pipes.

4. Bending The heated steel pipe can be bent on the manual pipe bending device.

Core Elbow

The cored pipe is to use the mandrel to bend the pipe back along the mold on the pipe bender. The function of the mandrel is to prevent the deformation of the section when the pipe is bent. The form of the mandrel includes round head type, pointed head type, spoon type, one-way joint type, universal joint type, flexible shaft type, etc.

a cored bend depends on the shape, size, and position of the mandrel extending into the tube.

Coreless elbow

Coreless pipe bending uses the reverse deformation method on the pipe bending machine to control the deformation of the steel pipe section. It makes the steel pipe give a certain amount of reverse deformation before entering the bending deformation zone so that the outer side of the steel pipe protrudes outward. To offset or reduce the deformation of the section of the steel pipe when it is bent, so as to ensure the quality of the bent pipe.

Coreless bends are widely used. When the bending radius of the steel pipe is greater than 1.5 times the pipe diameter, a coreless bend is generally used. Only for steel pipes with larger diameters and thinner wall thicknesses are cored bends used.

In addition, the bending methods include top pressure bending, intermediate frequency bending, flame bending, and extrusion bending.

Steel Pipe

There are two types of steel pipes: seamless steel pipes and seamed steel pipes.

1. Seamless steel pipe

Seamless steel pipes are divided into hot-rolled pipes, cold-drawn pipes, extruded pipes, etc. According to the cross-sectional shape, it can be divided into two types: round and special-shaped, and special-shaped steel pipes include square, oval, triangle, star, and so on. According to different uses, there are thick-walled and thin-walled tubes, and thin-walled tubes are mostly used for sheet metal parts.

2. Seamed steel pipe

Seamed steel pipes, also known as welded steel pipes, are welded with steel strips. There are two types of galvanized and non-galvanized. The former is called a white iron pipe and the latter is called a black iron pipe.

The size marking method of the steel pipe is: outer diameter × wall thickness × length, such as pipe D60×10×6000

Connection method of sheet metal parts:

Sheet metal parts are composed of many parts, and the parts must be connected in a certain way to form a complete product. The commonly used connection methods are welding riveting, screw connection, and expansion joint. The connection between the steel pipes also adopts the above methods. About Welding, Riveting, Screwing

An expansion joint is a connection method that uses the deformation of steel pipe and tube sheets to achieve sealing and fastening. It can use mechanical, explosive, and hydraulic methods to expand the diameter of the steel pipe to cause plastic deformation of the steel pipe and elastic deformation of the hole wall of the tube plate. The joint of the plate has sufficient expansion joint strength (pull-off force) to ensure that the steel pipe will not be pulled out of the pipe hole when the joint is working (after being stressed). At the same time, it should also have good sealing strength (pressure resistance), so as to ensure that the medium in the equipment will not leak from the joint under the working pressure.

Like this page? Share it with your friends!