If you do not know about stainless steel, then be sure to read this article, it will be comprehensive, systematic to take you to understand the type of stainless steel, characteristics, applications and a series of issues, and so you will find that this article covers almost all the knowledge about stainless steel, I hope to help you.

History of Stainless Steel

In the old days before stainless steel was invented, mankind was still exploring the world with bronze and iron, but one disadvantage of bronze and iron is that they rust, especially when exposed to harsh environments for a long period of time, which can lead to a decline in their performance.

By the early 1900s, thanks to the efforts of scientists, they discovered that combining elements such as chromium and nickel with iron could create a metal property never before seen – corrosion resistance. This discovery marked the introduction of stainless steel.

With the development of science and technology, stainless steel from the initial single species derived from a variety of different grades and properties of the type. Various different fields have also appeared in its figure, the application is extremely wide.

Production of different types of stainless steel

In fact, the different types of stainless steel is in the production of different components added to the chemistry, the proportion of various components are not the same, so that the production of stainless steel will show different characteristics to achieve different purposes.

Carbon

Carbon content in stainless steel will have a greater impact on its performance, such as high carbon content of stainless steel will show high hardness and strength, toughness and corrosion resistance is low; on the contrary, low carbon content will reduce the hardness and strength, improve toughness and corrosion resistance.

Chromium

The addition of chromium to the production of stainless steel confers many important properties.

- Corrosion resistance: Chromium will react with oxygen in the air to form a layer of chromium oxide on the surface, which can effectively prevent corrosion, and the higher the chromium content, the better the effect.

- High Temperature Resistance: Chromium can effectively improve the high temperature resistance of stainless steel.

- Strength and hardness: Chromium also increases the hardness and strength of stainless steel, making it more durable.

Nickel

Add appropriate nickel in stainless steel, can make stainless steel is not easy to receive corrosive media erosion; improve the strength and toughness of stainless steel, can withstand greater pressure and impact; containing can make it have better molding and weldability; in addition nickel can make the surface of the stainless steel is more smooth, easy to clean.

The five main types and properties of stainless steel

Although it is possible to make more than 1,000 different types of stainless steel by controlling the proportions of ingredients added to the production of stainless steel, they can all be categorized into the following 3 main groups.

Austenitic stainless steel

Want to make austenitic stainless steel, then the main elements are chromium and nickel, and the content of nickel is at least 8%, this is because nickel can play a role in stabilizing the austenitic structure, and give stainless steel good corrosion resistance, toughness and formability.

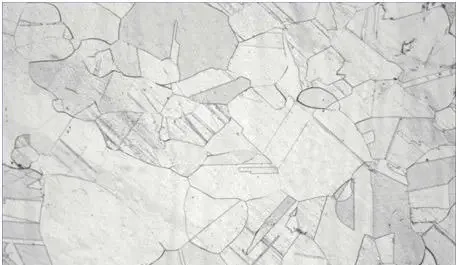

If you use a metallurgical microscope to observe austenite, you will find that it is composed of equiaxed polygonal grains with twinned crystals within the grains, which is often referred to as face-centered cubic structure. This kind of stainless steel is our usual and most common class (such as 304, 316, 301), non-magnetic, good corrosion resistance, easy to form and weld.

Ferritic Stainless Steel

Unlike austenitic, ferritic stainless steel’s main content is chromium, and will also contain elements such as manganese and nickel, but there is no requirement for nickel content. The corrosion resistance of ferritic stainless steel is also better.

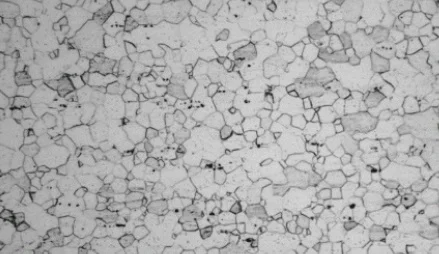

Ferrite is characterized by a body-centered cubic lattice structure and is magnetic, but it has low strength and toughness, and is commonly found in 409, 430, and 434.

Martensitic Stainless Steel

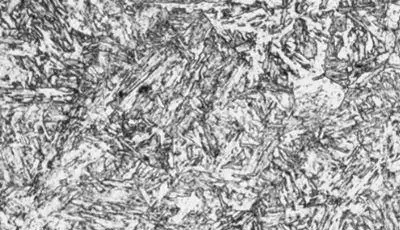

Like other stainless steels, martensitic stainless steel is an alloy of iron, chromium, and some other elements with a body-centered cubic lattice structure that is magnetic. You can also adjust its mechanical properties through heat treatment, so that its strength, hardness and wear resistance are greatly improved, but its toughness and corrosion resistance are poor.

The high hardness and strength of martensitic stainless steel is determined by its unique crystal structure and high carbon content, it is more suitable for stamping, forging molds and some cutting tools and so on.

Duplex (Ferritic-Austenitic) Stainless Steel

Let’s explain the duplex stainless steel, the so-called duplex refers to the ferrite phase and austenite phase about half each, so that the duplex stainless steel synthesizes the characteristics of ferrite and austenite, of course, this ratio can also be adjusted according to your actual needs, we have two common ferrite and austenite ratio:

- 70%-30%: This is the most common ratio, so that the stainless steel has good comprehensive performance.

- 50%-50%: This is the ideal ratio for higher strength and toughness of stainless steel.

We can also adjust their proportions depending on the specific application and the effect you want to achieve:

- If you want more strength and toughness, then you can increase the percentage of austenite.

- If you want stainless steel to be more corrosive, you can try increasing the percentage of ferrite.

- We mentioned earlier that austenite has good molding properties, and if you want that effect, you can increase the percentage of austenite.

- The higher nickel content in austenite makes it more costly, so if you want to reduce the cost, reduce the percentage of austenite appropriately.

Duplex stainless steel is superior in strength, toughness, corrosion and impact resistance, and it is well suited for use in more extreme environments, such as oil and gas, shipbuilding, and nuclear energy.

Precipitation-hardening (PH) Stainless Steel

PH steel is stainless steel through a heat treatment process called precipitation hardening, which further improves its strength and hardness while maintaining the original stainless steel properties, so its durability is outstanding.

The hardness and strength of PH steel is the highest among all stainless steels, even comparable with some low carbon steels; and it also has good wear resistance and high temperature resistance, which is applicable to more occasions. It will be used in some cutting-edge industries, such as aerospace, military, oil drilling and other industries.

Common types of austenitic stainless steel

Grade 301 Stainless Steel

The main components of 301 stainless steel are: 17%Cr, 7%Ni, 2%Mn, ≤0.15%C, ≤1.0%Si, ≤03%S, and ≤0.04%P. It has a melting point between 1399-1421°C, a density of 7.88g/cm³, and a tensile elastic modulus of 193 GPa.

This is 301 stainless steel has excellent strength, hardness, corrosion resistance and ductility, and when you cold work it, it will exhibit good strength and ductility.

It has some resistance to most corrosive media, such as chemicals, salt water, etc., but if it is used in high-temperature or strongly corrosive environments, its corrosion resistance will be out of reach.

301 stainless steel is mainly used for: automobile exhaust pipes, springs, connectors, medical equipment, food processing equipment and so on.

Grade 302 Stainless Steel

The main compositions of 302 stainless steel are: 17.00%~19.00%Cr, 8.00%~10.00%Ni, ≤1.00%Si, ≤0.030%S, ≤0.045%P, ≤2.00%Mn, ≤0.15%C. The melting point is between 1398~1420 ℃, the density is 8.03 g/cm³, and the tensile strength (RM/MPa): ≥520.

The corrosion resistance of 302 stainless steel is still very good, especially in the milder atmosphere and seawater under the performance is excellent; its workability is also very good, such as stamping and stretching, and cold working can improve its strength and hardness.

302 stainless steel is suitable for the manufacture of storage tanks, medical equipment, kitchenware, architectural and decorative materials.

Grade 303 Stainless Steel

The main components of 303 stainless steel are chromium (18%) and nickel (9%), due to the addition of sulfur and selenium to it, so that its machinability is improved, easy to cut, more popular in the machining industry. However, the addition of sulfur has an impact on its corrosion resistance, but in the regular environment can maintain good corrosion resistance.

It is important to note that 303 stainless steel is non-magnetic, but can be slightly magnetic if heavily cold worked, and it cannot be hardened by heat treatment.

Therefore, 303 stainless steel is suitable for making high-precision gears and shafts, bushings, valve bodies, valves and so on.

Grade 304 Stainless Steel

304 is one of the more common austenitic stainless steels, thanks to its excellent machinability for turning, milling, drilling, stamping, welding and many other processes, making it widely used in many industries.

Its high chromium and nickel content allows it to maintain excellent corrosion resistance in a variety of different environments, and it can withstand temperatures up to 800 degrees Celsius.

304 stainless steel has excellent overall properties and is favored by the food and medical industries, dairy equipment and household appliances, etc. SpaceX uses 304 stainless steel for its rocket housings.

Grade 309 Stainless Steel

Compared with 304 stainless steel (18%-20% chromium, 8%-10.5% nickel), 309 stainless steel has higher chromium (23.00-25.00%) and nickel (12.00-15.00%), so its corrosion resistance is better, and its oxidation resistance at high temperature is also better, and it can be used for a long time and stably at high temperature, and its heat resistance is as high as 980℃.

Due to this property, 309 stainless steel is ideal for equipment that requires high temperature operation and high oxidation resistance.

Grade 316 Stainless Steel

316 stainless steel is also one of the more common types of austenitic stainless steel, which adds about 2% to 3% molybdenum to the basic austenitic composition, which greatly improves 316’s resistance to pitting and crevice corrosion, especially in chloride environments.

And the carbon content of 316 needs to be kept below 0.08%, this is to improve its weldability.

Most of the 316 stainless steel is used in the food and medical industry, including some corrosion-resistant containers, piping, food contact equipment, and so on.

Grade 317 Stainless Steel

The composition of 317 stainless steel is based on the 316 increased chromium, nickel and molybdenum content, which makes it better than 316 corrosion resistance, strength and toughness. Even acidic and alkaline media can’t take it. Moreover, in the production of 317 stainless steel, less waste and wastewater is produced, and the recycling rate is higher.

Some of the more demanding working environment of the industry is more suitable for the use of 317 stainless steel, such as the chemical industry, the oil and gas industry, the nuclear industry and ships and other fields.

Grade 321 Stainless Steel

321 stainless steel can be said to be a variant of 304 stainless steel, its properties are similar to those of 304, but 321 adds the metal titanium on top of that, which gives it better intergranular corrosion resistance and high temperature strength.

It has been tested that 321 stainless steel will exhibit excellent stress-breaking properties and creep resistance at high temperatures, which makes it suitable for welded structures used at high temperatures.

321 stainless steel is suitable for use in the manufacture of machinery and equipment in the open field, such as oil, coal, chemical and other fields.

Grade 347 Stainless Steel

Like 321 stainless steel, 347 stainless steel also adds some metal to 304, but it is not titanium metal, but niobium metal, the main purpose is to stabilize the austenite phase and improve its resistance to intergranular corrosion. Of course, some 347 stainless steel will also add the metal titanium and molybdenum, in order to further improve its performance.

The machinability and weldability of 347 stainless steel are very good, which can meet the requirements for the production of various complex parts; due to its excellent corrosion resistance and high temperature resistance, it is suitable for the manufacture of equipment for petroleum refining and natural gas desulfurization.

Common Types of Ferritic Stainless Steel

| Grade | Standard | Main Elements | Characteristics | Applications |

|---|---|---|---|---|

| 409 | AISI | Cr10.5-11.75 | Low price, easy to process, general corrosion resistance | Automotive exhaust system components, appliance trim |

| 430 | AISI | Cr16-18 | Good corrosion resistance, formability, and weldability | Decorative parts, cookware, building components |

| 430F | AISI | Cr16-18 (Ti) | Excellent formability and weldability | Low-carbon steel substitute |

| 430LX | AISI | Cr16-18 (low carbon) | Excellent welding performance | Deep-drawn parts, automotive exhaust system components |

| 434 | AISI | Cr17-19 | Good corrosion resistance and weldability | Automotive trim, appliance parts |

| 439 | AISI | Cr17-19 (Nb) | Excellent formability and high-temperature resistance | Deep-drawn parts, sinks |

| 441 | AISI | Cr18-20 | Good corrosion resistance and high-temperature resistance | Heat exchangers, catalytic converters |

| 444 | AISI | Cr18-20 (Nb, Mo) | Excellent high-temperature resistance and oxidation resistance | Exhaust manifolds, high-temperature components |

| 446 | AISI | Cr23-26 | Excellent high-temperature resistance and oxidation resistance | Deep-drawn parts sinks |

Common Types of Martensitic Stainless Steel

| Grade | Standard | Main Elements | Characteristics | Applications |

|---|---|---|---|---|

| 403 | AISI | Cr12Mo0.5 | Low price, high strength, good wear resistance | Knives, scissors, bearings |

| 410 | AISI | Cr12Mo0.5 | Good wear resistance and corrosion resistance | Knives, valves, pumps |

| 414 | AISI | Cr14Mo0.5 | Higher hardness and strength | Knives, dies |

| 416 | AISI | Cr12Mo0.5S | Good machinability and wear resistance | Screws, bolts, bearings |

| 420 | AISI | Cr13Mo0.4 | Good hardness and wear resistance, heat treatable | Knives, cutlery, mechanical parts |

| 422 | AISI | Cr13Mo0.7 | Improved corrosion resistance and toughness | Good hardness and wear resistance, heat-treatable |

Common Types of Duplex (Ferritic-Austenitic) Stainless Steels

| Grade | Standard | Main Elements | Characteristics | Applications |

|---|---|---|---|---|

| 201N | AISI | Cr18Mn6Ni5N | Low price, strong resistance to nitrogen corrosion | Food processing, chemical industry |

| 2205 | AISI | Cr18Mn6Ni4Mo0.5Cu | Good corrosion resistance, strength, and toughness | Flue gas desulfurization, marine aquaculture |

| 2304 | AISI | Cr18Ni10Mo2 | Excellent corrosion resistance, strength, and toughness | Petrochemical industry, offshore engineering |

| 2505 | AISI | Cr21Ni5Mo3Cu1.5 | Excellent corrosion resistance, strength, and toughness | Flue gas desulfurization, marine aquaculture |

| S31803 | UNS | Cr18Ni5Mo3Cu | Good corrosion resistance, strength, and toughness | Shipbuilding, offshore engineering |

| S32205 | UNS | Cr18Ni5Mo3Cu0.5 | Good corrosion resistance, strength, and toughness | Petrochemical industry, offshore engineering |

| SAF 2205 | ASTM | Cr18Mn6Ni4Mo0.5Cu | Good resistance to chloride corrosion | Flue gas desulfurization, marine aquaculture |

Common Types of Precipitation Hardening (PH) Stainless Steels

| Grade | Standard | Main Elements | Characteristics | Applications |

|---|---|---|---|---|

| 17-4PH | AISI | Cr17Ni4MoCu | High strength, high toughness, good corrosion resistance | Aerospace, nuclear industry, petrochemical industry |

| 17-7PH | AISI | Cr17Ni7Mo | Extremely high strength and hardness | Knives, dies, bearings |

| A286 | AISI | Cr15Ni25Ti2MoAl | Good high-temperature strength and corrosion resistance | Aerospace, gas turbines |

| 630 | AISI | Cr17Ni4CuNb | Good strength, toughness, and corrosion resistance | Chemical, petrochemical, shipbuilding |

What do the grades of stainless steel mean?

The grade of stainless steel actually represents the difference in properties, composition, and uses of their material, and this grade usually uses a string of numbers or letters on top of the numbers. The numbers represent the main types of stainless steel, while the letters indicate additional elements. Next together to see what they specifically represent.

numeric

- 200 series: represents the austenitic stainless steel, this type of stainless steel contains the main components of chromium and manganese, nickel content is low, they have good corrosion resistance, processing and welding up is also very convenient, but the strength is low.

- 300 series: also stands for austenitic stainless steel, this type of stainless steel to chromium and nickel-based, good corrosion resistance, strength and toughness are also very good. 304 and 316 is the 300 series of stainless steel we are most commonly found in the two.

- 400 series: represents ferritic stainless steel, this kind of stainless steel is different from 300 series, its main component is chromium element, and the content of nickel is little or even no, they have a certain degree of magnetism, the strength is good, and more wear-resistant, but the performance of corrosion resistance is not as good as that of 200 and 300 series.

- 500 Series: Representing martensitic stainless steel, the main elements are chromium and nickel, these stainless steels have high strength and hardness, but their corrosion resistance is relatively poor.

- 600 series: represents precipitation hardening stainless steel, which is based on stainless steel by adding copper, molybdenum, titanium and other elements to improve the strength and hardness. This type of stainless steel has strong comprehensive performance, strength, hardness, corrosion resistance, high temperature resistance are very good.

letter (of the alphabet)

- L: denotes a low carbon stainless steel, which usually has a carbon content of less than 0.03%. This type of stainless steel is easier to weld and has better resistance to intergranular corrosion.

- N: Indicates stainless steel with a high nitrogen content, while nitrogen improves the strength and toughness of stainless steel.

- S: Indicates stainless steel containing sulfur. Adding sulfur to stainless steel appropriately can make it easier to process.

- Ti: denotes titanium-containing metal. Adding titanium to stainless steel enhances its resistance to corrosion and high temperatures.

- Mo: denotes stainless steel containing molybdenum, which improves the corrosion resistance of stainless steel, especially against chlorides.

- Cu: indicates copper-containing stainless steel. Copper gives stainless steel better strength and hardness.

For example, the austenitic 316 stainless steel, his carbon content is about 0.08%, while the carbon content of 316L is under 0.03%.

What are the different standards for stainless steel grades?

- American Standard (ASTM): This is customized by the American Society for Testing and Materials (ASTM), is also currently the world’s common standards, we often say that 304 is ASTM304 (American Standard) is a simplified version of the. 316 is also a simplified version of ASTM316.

- European standard (EN): this standard is developed by the European Committee for Standardization (CEN), many countries in Europe are using a standard, basically EN at the beginning, followed by a string of numbers, such as EN 1.4301 means 304 stainless steel.

- Japanese Standard (JIS): Developed by the Japan Industrial Standardization Committee (JISC), the grade is prefixed with SUS, e.g. SUS304 means 304.

- Chinese National Standard (GB): This is developed by the Chinese National Standardization Administration Committee (SAC) and is generally expressed in terms of the elements of the material, for example, GB 1Cr18Ni9 stainless steel is equivalent to 304.

Below are some common grades of stainless steel and their equivalents in different standards:

| Grade | ASTM | EN | JIS | GB |

|---|---|---|---|---|

| 304 | ASTM304 | EN1.4301 | SUS304 | 1Cr18Ni9 |

| 316 | ASTM316 | EN1.4401 | SUS316 | 00Cr18Ni14Mo2 |

| 201 | ASTM201 | EN1.4306 | SUS201 | 1Cr18Ni5 |

| 430 | ASTM430 | EN1.4016 | SUS430 | 1Cr13Ni4 |

| 17-4PH | A17-4PH | EN1.405 | SUS416 | 00Cr17Ni7Mo4 |

How do you determine the right type for your needs?

If you want to buy stainless steel, or to make stainless steel parts, but you don’t know a lot about stainless steel, it will cause you to hesitate when choosing. The following is our experience accumulated with years of processing stainless steel, to teach you some aspects you need to pay attention to when shopping.

Your Environment

The first thing you need to consider is the environment in which the stainless steel product you are buying will be used, what chemicals it will be exposed to, whether it will be subjected to strong impacts and so on. Then you can choose the right stainless steel according to your actual situation. For example, your stainless steel products will be exposed to seawater or acidic environment for a long time, then you’d better choose stainless steel with good corrosion resistance, like 316 or 2205.

Formability or Weldability

Here you have to consider whether you need to process the stainless steel to make it look the way you want. For example, welding, forging, stamping or machining, if you need to, then you’ll want to choose stainless steels that are easier to work with. Austenitic and ferritic stainless steels have good machinability and are both good choices.

Strength

Next you also need to consider how much load you want the stainless steel to be able to withstand and how high the need for strength is. If, however, you need high strength stainless steel, think about using martensitic stainless steel or precipitation hardening stainless steel, both of which have a high degree of hardness.

Toughness

Then consider the toughness of the stainless steel you need, in the use of the process will not withstand shock and vibration, if there is a need for it, austenitic and duplex stainless steel are good choices, their are very good toughness.

Cost and Availability

Cost may be your purchase of stainless steel is more focused, there are many types of stainless steel, the price difference between them is also very big, however, in the purchase of you need to meet your use of the needs of the first, and then try to reduce the cost on the basis of this.

Best Types of Stainless Steel by Industry

Each industry has different needs for stainless steel performance, so you need to choose the right stainless steel in order to meet the needs of a particular industry on its performance, the following are some of the industries we recommend the more suitable stainless steel grades.

aerospace industry

We all know that the aerospace industry is used in a harsh environment. Stainless steels used in this industry need to withstand a lot of load, shock and vibration, so martensitic and precipitation hardening stainless steels are great choices for this purpose.

Healthcare industry

Medical industry is more special, some medical devices may even be directly implanted in the body, so rust is absolutely not, here is more recommended 316L stainless steel, its carbon content is lower, effectively reducing the risk of intergranular corrosion, and some common appliances and equipment can be used 304 stainless steel.

maritime industry

The environment in which the marine industry is located is also relatively harsh, long-term erosion by seawater, and sometimes receive the impact of the wind and waves, here is more recommended 316 and duplex stainless steel, they are suitable for the environment in the ocean, and can effectively prevent the erosion of chloride solution, and their hardness and strength are very good.

Oil and gas industry

316 stainless steel is suitable for use in the production, storage and transportation of oil and gas, it can effectively resist the corrosion of oil and gas, duplex stainless steel is suitable for some applications such as undersea pipelines and drilling equipment.

Chemical industry

In the chemical industry, will come into contact with a variety of corrosive gases and liquids, especially test the corrosion resistance of stainless steel, 316 and 2205 stainless steel is a very good choice, their corrosion resistance is excellent, and the strength and toughness is also very good.

Food processing industry

Stainless steel used in the food industry is basically 304 and 316, they have been tested by the market for many years and are fine. Our common stainless steel cutlery, kitchenware and cups are basically 304 or 316.

Myths about stainless steel

“All Stainless Steel is the same.”

There are about 1000 different types of stainless steel, so they are all different and have their own uses. Nowadays, the industry usually categorizes them according to their crystal structure – austenitic, ferritic, martensitic, duplex (austenitic plus ferrite), precipitation-hardening stainless steel – and there are even more subdivided types under these five main categories.

“Stainless Steel doesn’t rust.”

Stainless steel is called stainless steel, because relative to other metals it has excellent corrosion resistance, this ability depends mainly on its chromium content and the thickness of the surface passivation film, the higher the chromium content, the thicker the passivation film, the stronger its corrosion resistance. But stainless steel is not completely will not rust, in some conditions or rust.

Some stainless steels with low chromium content, like 403, can still rust in wet or corrosive environments. Even stainless steels with a high chromium content like 304 can cause rust if the surface is subjected to breakage, scratches or welded.

“Stainless steel is not magnetic”

Many people think that stainless steel is not magnetic, as long as the magnet can be sucked are not stainless steel, this is actually wrong, like austenitic stainless steel, in the annealed state is not magnetic or slightly magnetic, if the later after cold processing or welding, it will show magnetic characteristics. Martensitic and ferritic stainless steel, in the annealed state is magnetic.

“Stainless steel is expensive”

Stainless steel is indeed more expensive, while carbon steel is 1/3 or 1/2 the price of stainless steel, but the extra performance of stainless steel will make up for its price disadvantage, due to the excellent performance of stainless steel, it is irreplaceable in many applications. If your application requires corrosion resistance, strength, toughness, etc., then stainless steel is a good choice.

If you use carbon steel for your application, then you will need to paint him to prevent rusting, which may seem like a low cost, but the cost of later maintenance will definitely be higher than if you use stainless steel.

“All Stainless Steels have the same corrosion resistance.”

This view is actually wrong, although they are both called stainless steel but the corrosion resistance is different. The factors that cause this difference are the content of chromium and the addition of other metals such as nickel, molybdenum and copper. They can all effectively prevent corrosion, but if the added content is different, then their corrosion resistance will vary.

Choosing the right stainless steel fabrication partner

If you are looking to purchase stainless steel or stainless steel parts, here are a few suggestions to help you.

Experience and expertise

When choosing a partner, their experience and expertise in stainless steel fabrication is important so that they can recommend the right material and fabrication process for your needs and can share with you examples of relevant experience in your industry or application. You can also visit their factory to see their fabrication equipment.

quality control

Stainless steel requires strict quality control measures during the manufacturing process, you can ask them how they carry out the process control and also take a look at their quality certification documents. You can ask your supplier to provide inspection reports and test reports at the time of delivery.

Price and delivery time

You can find more suppliers and get multiple quotes to compare their prices and delivery deadlines. This quote should ideally be very detailed and include costs such as materials, shipping and molds.

Communication and services

This needs to be based on your own sense of how easy it is for you to communicate with them, whether they can understand your needs, and whether they respond and deal with questions in a timely manner when they arise.

summarize

Through an in-depth discussion of the main types of stainless steel, it’s easy to see that stainless steel has a good combination of properties and many applications. We hope this article can help you understand and master their properties and uses, which will be helpful to you in the future, no matter whether you are choosing materials, designing products or choosing suppliers.